Page 120 - Welding Robots Technology, System Issues, and Applications

P. 120

Robotic Welding: System Issues 107

welding parameters are the voltage, the wire feed rate, and the torch

speed. Technically, the voltage and the wire feed rate are analog signals

commanded to the welding power source, and generated from the robot

controller or process PLC. The torch speed is the desired speed

commanded to the robot TCP for coordinated motion.

2. Secondary inputs: variables defined when the process is selected and

before any welding service. Using again as example the GMAW process

those parameters include the type or composition of the shielding gas, the

flow of gas during the process, the torch angle, and the type and size of

the wire to use.

3. Fixed inputs: parameters that are fixed and cannot be changed by the

user. These parameters are usually an imposition of the selected welding

process, of the current welding procedure or of the physical setup.

Parameters of this type include the joint geometry, plate thickness,

physical properties of the plate metal, etc.

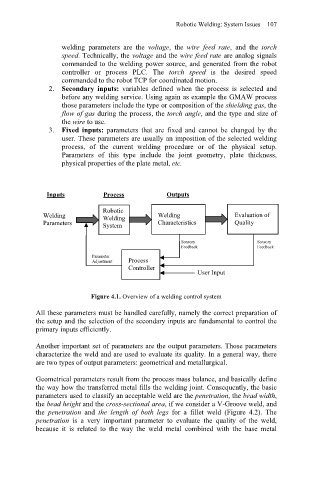

Inputs Process Outputs

Robotic

Welding Welding Welding Evaluation of

Parameters System Characteristics Quality

Sensory Sensory

Feedback Feedback

Parameter

Adjustment Process

Controller

User Input

Figure 4.1. Overview of a welding control system

All these parameters must be handled carefully, namely the correct preparation of

the setup and the selection of the secondary inputs are fundamental to control the

primary inputs efficiently.

Another important set of parameters are the output parameters. Those parameters

characterize the weld and are used to evaluate its quality. In a general way, there

are two types of output parameters: geometrical and metallurgical.

Geometrical parameters result from the process mass balance, and basically define

the way how the transferred metal fills the welding joint. Consequently, the basic

parameters used to classify an acceptable weld are the penetration, the bead width,

the bead height and the cross-sectional area, if we consider a V-Groove weld, and

the penetration and the length of both legs for a fillet weld (Figure 4.2). The

penetration is a very important parameter to evaluate the quality of the weld,

because it is related to the way the weld metal combined with the base metal