Page 125 - Welding Robots Technology, System Issues, and Applications

P. 125

112 Welding Robots

4.2 Control of the Welding Process

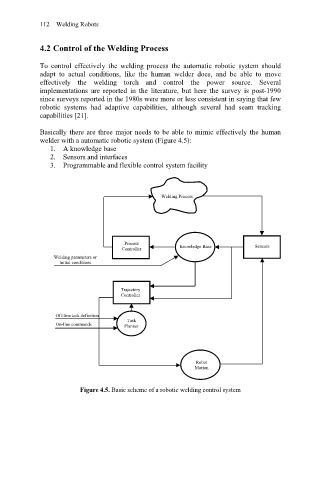

To control effectively the welding process the automatic robotic system should

adapt to actual conditions, like the human welder does, and be able to move

effectively the welding torch and control the power source. Several

implementations are reported in the literature, but here the survey is post-1990

since surveys reported in the 1980s were more or less consistent in saying that few

robotic systems had adaptive capabilities, although several had seam tracking

capabilities [21].

Basically there are three major needs to be able to mimic effectively the human

welder with a automatic robotic system (Figure 4.5):

1. A knowledge base

2. Sensors and interfaces

3. Programmable and flexible control system facility

Welding Process

Process

Controller Knowledge Base Sensors

Welding parameters or

Initial conditions

Trajectory

Controller

Off-line task definition

Task

On-line commands

Planner

Robot

Motion

Figure 4.5. Basic scheme of a robotic welding control system