Page 127 - Welding Robots Technology, System Issues, and Applications

P. 127

114 Welding Robots

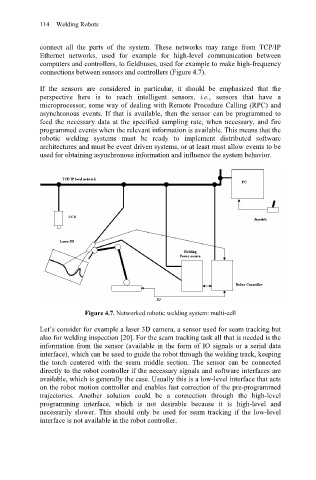

connect all the parts of the system. These networks may range from TCP/IP

Ethernet networks, used for example for high-level communication between

computers and controllers, to fieldbuses, used for example to make high-frequency

connections between sensors and controllers (Figure 4.7).

If the sensors are considered in particular, it should be emphasized that the

perspective here is to reach intelligent sensors, i.e., sensors that have a

microprocessor, some way of dealing with Remote Procedure Calling (RPC) and

asynchronous events. If that is available, then the sensor can be programmed to

feed the necessary data at the specified sampling rate, when necessary, and fire

programmed events when the relevant information is available. This means that the

robotic welding systems must be ready to implement distributed software

architectures and must be event driven systems, or at least must allow events to be

used for obtaining asynchronous information and influence the system behavior.

Figure 4.7. Networked robotic welding system: multi-cell

Let’s consider for example a laser 3D camera, a sensor used for seam tracking but

also for welding inspection [20]. For the seam tracking task all that is needed is the

information from the sensor (available in the form of IO signals or a serial data

interface), which can be used to guide the robot through the welding track, keeping

the torch centered with the seam middle section. The sensor can be connected

directly to the robot controller if the necessary signals and software interfaces are

available, which is generally the case. Usually this is a low-level interface that acts

on the robot motion controller and enables fast correction of the pre-programmed

trajectories. Another solution could be a connection through the high-level

programming interface, which is not desirable because it is high-level and

necessarily slower. This should only be used for seam tracking if the low-level

interface is not available in the robot controller.