Page 145 - Welding Robots Technology, System Issues, and Applications

P. 145

132 Welding Robots

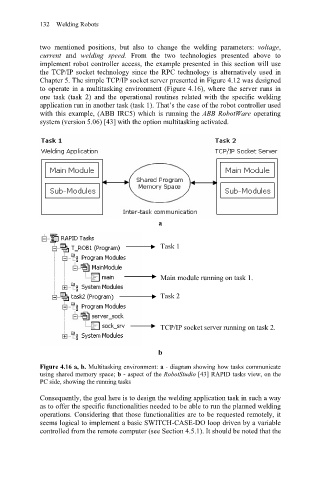

two mentioned positions, but also to change the welding parameters: voltage,

current and welding speed. From the two technologies presented above to

implement robot controller access, the example presented in this section will use

the TCP/IP socket technology since the RPC technology is alternatively used in

Chapter 5. The simple TCP/IP socket server presented in Figure 4.12 was designed

to operate in a multitasking environment (Figure 4.16), where the server runs in

one task (task 2) and the operational routines related with the specific welding

application run in another task (task 1). That’s the case of the robot controller used

with this example, (ABB IRC5) which is running the ABB RobotWare operating

system (version 5.06) [43] with the option multitasking activated.

a

Task 1

Main module running on task 1.

Task 2

TCP/IP socket server running on task 2.

b

Figure 4.16 a, b. Multitasking environment: a - diagram showing how tasks communicate

using shared memory space; b - aspect of the RobotStudio [43] RAPID tasks view, on the

PC side, showing the running tasks

Consequently, the goal here is to design the welding application task in such a way

as to offer the specific functionalities needed to be able to run the planned welding

operations. Considering that those functionalities are to be requested remotely, it

seems logical to implement a basic SWITCH-CASE-DO loop driven by a variable

controlled from the remote computer (see Section 4.5.1). It should be noted that the