Page 149 - Welding Robots Technology, System Issues, and Applications

P. 149

136 Welding Robots

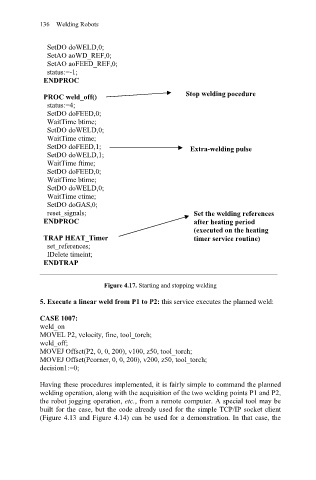

SetDO doWELD,0;

SetAO aoWD_REF,0;

SetAO aoFEED_REF,0;

status:=-1;

ENDPROC

Stop welding pocedure

PROC weld_off()

status:=4;

SetDO doFEED,0;

WaitTime btime;

SetDO doWELD,0;

WaitTime ctime;

SetDO doFEED,1; Extra-welding pulse

SetDO doWELD,1;

WaitTime ftime;

SetDO doFEED,0;

WaitTime btime;

SetDO doWELD,0;

WaitTime ctime;

SetDO doGAS,0;

reset_signals; Set the welding references

ENDPROC after heating period

(executed on the heating

TRAP HEAT_Timer timer service routine)

set_references;

IDelete timeint;

ENDTRAP

__________________________________________________________________

Figure 4.17. Starting and stopping welding

5. Execute a linear weld from P1 to P2: this service executes the planned weld:

CASE 1007:

weld_on

MOVEL P2, velocity, fine, tool_torch;

weld_off;

MOVEJ Offset(P2, 0, 0, 200), v100, z50, tool_torch;

MOVEJ Offset(Pcorner, 0, 0, 200), v200, z50, tool_torch;

decision1:=0;

Having these procedures implemented, it is fairly simple to command the planned

welding operation, along with the acquisition of the two welding points P1 and P2,

the robot jogging operation, etc., from a remote computer. A special tool may be

built for the case, but the code already used for the simple TCP/IP socket client

(Figure 4.13 and Figure 4.14) can be used for a demonstration. In that case, the