Page 177 - Welding Robots Technology, System Issues, and Applications

P. 177

Read actual robot position/orientation: Robotic Welding: Application Examples 165

pcrob.ReadCurrRobTarget(result, channel);

where result is again a data structure of the appropriate type to hold a robtarget

position/orientation structure [9][10].

The process of accessing information from the robot controller and from the loaded

program modules is thus very simple, namely because the necessary data structures

are available from the above-mentioned software component. For example, the

code associated with the software button “Read RobT” of the application

“WeldPanel” (Figure 5.7) is represented in Figure 5.13.

CString msg;

float value = 9301;

nresult = m_pon.WriteNum(LPCTSTR("decision1"),&value);

msg.Format("Error: %d",nresult);

if (nresult != 0) AfxMessageBox(msg);

CString msg;

float value = 9401;

nresult = m_pon.WriteNum(LPCTSTR("decision1"),&value);

msg.Format("Error: %d",nresult);

if (nresult != 0) AfxMessageBox(msg);

startweld=1;

Sleep(100);

nresult = m_pon.ReadNum(LPCTSTR("weldpoint"),&value);

msg.Format("Error: %d",nresult);

CString msg;

float value = 123;

nresult = m_pon.WriteNum(LPCTSTR("decision1"),&value);

msg.Format("Error: %d",nresult);

if (nresult != 0) AfxMessageBox(msg);

startweld=0;

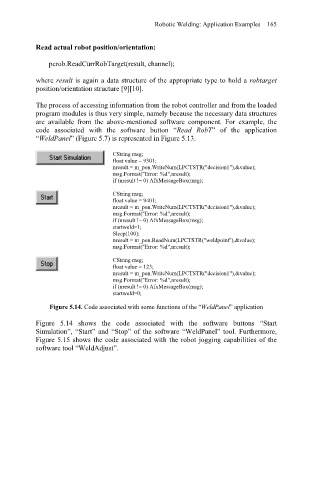

Figure 5.14. Code associated with some functions of the “WeldPanel” application

Figure 5.14 shows the code associated with the software buttons “Start

Simulation”, “Start” and “Stop” of the software “WeldPanel” tool. Furthermore,

Figure 5.15 shows the code associated with the robot jogging capabilities of the

software tool “WeldAdjust”.