Page 179 - Welding Robots Technology, System Issues, and Applications

P. 179

Robotic Welding: Application Examples 167

5.4.2 Software Components

Using software components is an interesting solution, because it simplifies the use

of certain features hiding the tricky details from the advanced user. Furthermore,

using “visual” components is also desirable, since they integrate well with the

available component containers. If the operating system is based on the Distributed

COM technology (DCOM), then ActiveX components are one of the obvious

solutions.

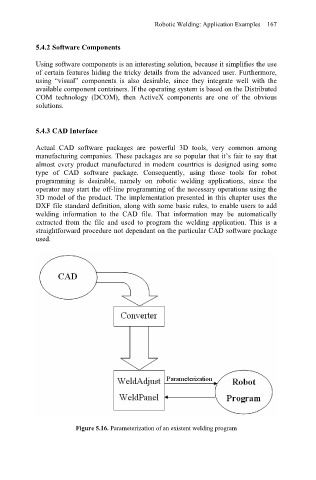

5.4.3 CAD Interface

Actual CAD software packages are powerful 3D tools, very common among

manufacturing companies. These packages are so popular that it’s fair to say that

almost every product manufactured in modern countries is designed using some

type of CAD software package. Consequently, using those tools for robot

programming is desirable, namely on robotic welding applications, since the

operator may start the off-line programming of the necessary operations using the

3D model of the product. The implementation presented in this chapter uses the

DXF file standard definition, along with some basic rules, to enable users to add

welding information to the CAD file. That information may be automatically

extracted from the file and used to program the welding application. This is a

straightforward procedure not dependant on the particular CAD software package

used.

Figure 5.16. Parameterization of an existent welding program