Page 184 - Welding Robots Technology, System Issues, and Applications

P. 184

172 Welding Robots

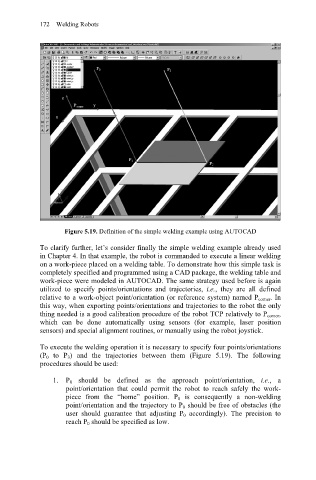

Figure 5.19. Definition of the simple welding example using AUTOCAD

To clarify further, let’s consider finally the simple welding example already used

in Chapter 4. In that example, the robot is commanded to execute a linear welding

on a work-piece placed on a welding table. To demonstrate how this simple task is

completely specified and programmed using a CAD package, the welding table and

work-piece were modeled in AUTOCAD. The same strategy used before is again

utilized to specify points/orientations and trajectories, i.e., they are all defined

relative to a work-object point/orientation (or reference system) named P corner. In

this way, when exporting points/orientations and trajectories to the robot the only

thing needed is a good calibration procedure of the robot TCP relatively to P corner,

which can be done automatically using sensors (for example, laser position

sensors) and special alignment routines, or manually using the robot joystick.

To execute the welding operation it is necessary to specify four points/orientations

(P 0 to P 3) and the trajectories between them (Figure 5.19). The following

procedures should be used:

1. P 0 should be defined as the approach point/orientation, i.e., a

point/orientation that could permit the robot to reach safely the work-

piece from the “home” position. P 0 is consequently a non-welding

point/orientation and the trajectory to P 0 should be free of obstacles (the

user should guarantee that adjusting P 0 accordingly). The precision to

reach P 0 should be specified as low.