Page 186 - Welding Robots Technology, System Issues, and Applications

P. 186

174 Welding Robots

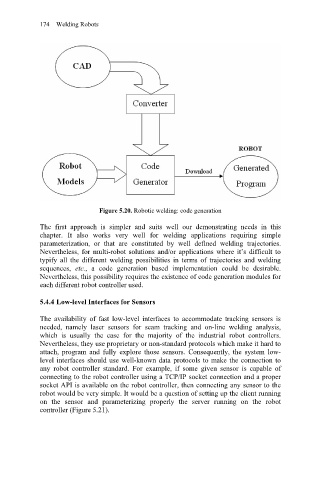

Figure 5.20. Robotic welding: code generation

The first approach is simpler and suits well our demonstrating needs in this

chapter. It also works very well for welding applications requiring simple

parameterization, or that are constituted by well defined welding trajectories.

Nevertheless, for multi-robot solutions and/or applications where it’s difficult to

typify all the different welding possibilities in terms of trajectories and welding

sequences, etc., a code generation based implementation could be desirable.

Nevertheless, this possibility requires the existence of code generation modules for

each different robot controller used.

5.4.4 Low-level Interfaces for Sensors

The availability of fast low-level interfaces to accommodate tracking sensors is

needed, namely laser sensors for seam tracking and on-line welding analysis,

which is usually the case for the majority of the industrial robot controllers.

Nevertheless, they use proprietary or non-standard protocols which make it hard to

attach, program and fully explore those sensors. Consequently, the system low-

level interfaces should use well-known data protocols to make the connection to

any robot controller standard. For example, if some given sensor is capable of

connecting to the robot controller using a TCP/IP socket connection and a proper

socket API is available on the robot controller, then connecting any sensor to the

robot would be very simple. It would be a question of setting up the client running

on the sensor and parameterizing properly the server running on the robot

controller (Figure 5.21).