Page 172 - Welding Robots Technology, System Issues, and Applications

P. 172

160 Welding Robots

5.3 Test Cases

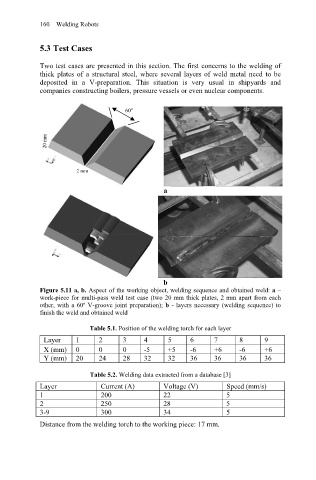

Two test cases are presented in this section. The first concerns to the welding of

thick plates of a structural steel, where several layers of weld metal need to be

deposited in a V-preparation. This situation is very usual in shipyards and

companies constructing boilers, pressure vessels or even nuclear components.

60º

20 mm

2 mm

a

b

Figure 5.11 a, b. Aspect of the working object, welding sequence and obtained weld: a –

work-piece for multi-pass weld test case (two 20 mm thick plates, 2 mm apart from each

other, with a 60º V-groove joint preparation); b - layers necessary (welding sequence) to

finish the weld and obtained weld

Table 5.1. Position of the welding torch for each layer

Layer 1 2 3 4 5 6 7 8 9

X (mm) 0 0 0 -5 +5 -6 +6 -6 +6

Y (mm) 20 24 28 32 32 36 36 36 36

Table 5.2. Welding data extracted from a database [3]

Layer Current (A) Voltage (V) Speed (mm/s)

1 200 22 5

2 250 28 5

3-9 300 34 5

Distance from the welding torch to the working piece: 17 mm.