Page 168 - Welding Robots Technology, System Issues, and Applications

P. 168

156 Welding Robots

The next information is the type of trajectory, to distinguish between welding

trajectories and approach/escape trajectories. After that should be specified the

welding current, and then the welding voltage. Finally, the welding speed is

specified. All these parameters are separated by spaces, constituting a definition

string. Consequently, a label on a welding trajectory is a string that looks like this

one:

WELD 0 150.0 20.0 10 0

which defines a welding trajectory (0 – welding, 1 – approach/escape, Figure 5.6),

with a welding current of 150 A, a welding voltage of 20 V, a welding speed of 10

mm/s and maximum precision in achieving the end-point.

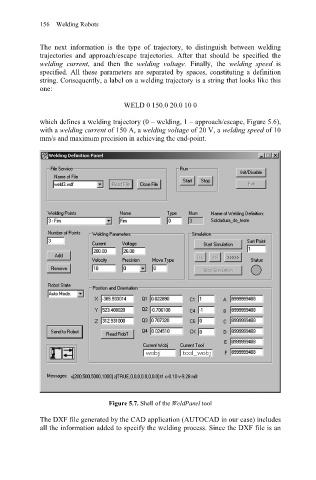

Figure 5.7. Shell of the WeldPanel tool

The DXF file generated by the CAD application (AUTOCAD in our case) includes

all the information added to specify the welding process. Since the DXF file is an