Page 45 - Welding Robots Technology, System Issues, and Applications

P. 45

Welding Robots

30

of several elements [4],[5]. These electrodes have better operational characteristics

than thoriated electrodes and can be used in welding carbon and stainless steels,

nickel and titanium alloys. Zirconiated tungsten electrodes are excellent for AC

due to its good arc starting, high resistance to contamination and small tip shape

deterioration.

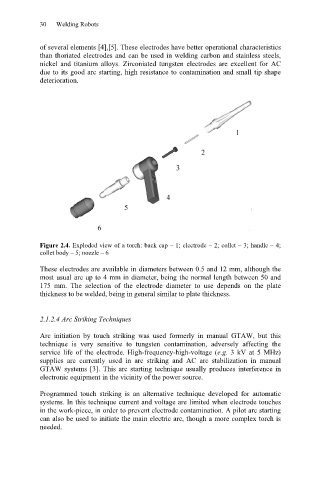

Figure 2.4. Exploded view of a torch: back cap – 1; electrode – 2; collet – 3; handle – 4;

collet body – 5; nozzle – 6

These electrodes are available in diameters between 0.5 and 12 mm, although the

most usual are up to 4 mm in diameter, being the normal length between 50 and

175 mm. The selection of the electrode diameter to use depends on the plate

thickness to be welded, being in general similar to plate thickness.

2.1.2.4 Arc Striking Techniques

Arc initiation by touch striking was used formerly in manual GTAW, but this

technique is very sensitive to tungsten contamination, adversely affecting the

service life of the electrode. High-frequency-high-voltage (e.g. 3 kV at 5 MHz)

supplies are currently used in arc striking and AC arc stabilization in manual

GTAW systems [3]. This arc starting technique usually produces interference in

electronic equipment in the vicinity of the power source.

Programmed touch striking is an alternative technique developed for automatic

systems. In this technique current and voltage are limited when electrode touches

in the work-piece, in order to prevent electrode contamination. A pilot arc starting

can also be used to initiate the main electric arc, though a more complex torch is

needed.