Page 47 - Welding Robots Technology, System Issues, and Applications

P. 47

Welding Robots

32

Reverse polarity may be of interest in welding aluminum alloys because of the

cathodic cleaning action of negative pole in the work-piece, that is the removal of

the refractory aluminum oxide layer. However alternating current is better adapted

to welding of aluminum and magnesium alloys, because it allows balancing

electrode heating and work-piece cleaning effects. Weld penetration depth obtained

with AC is between depth obtained with DCEN and DCEP, as illustrated in Figure

2.5.

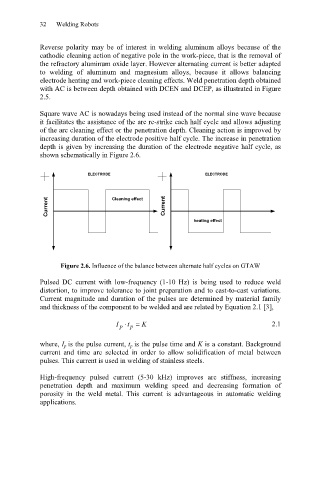

Square wave AC is nowadays being used instead of the normal sine wave because

it facilitates the assistance of the arc re-strike each half cycle and allows adjusting

of the arc cleaning effect or the penetration depth. Cleaning action is improved by

increasing duration of the electrode positive half cycle. The increase in penetration

depth is given by increasing the duration of the electrode negative half cycle, as

shown schematically in Figure 2.6.

ELECTRODE ELECTRODE

Current Cleaning effect Current

heating effect

Figure 2.6. Influence of the balance between alternate half cycles on GTAW

Pulsed DC current with low-frequency (1-10 Hz) is being used to reduce weld

distortion, to improve tolerance to joint preparation and to cast-to-cast variations.

Current magnitude and duration of the pulses are determined by material family

and thickness of the component to be welded and are related by Equation 2.1 [3],

I t K 2.1

p

p

where, I p is the pulse current, t p is the pulse time and K is a constant. Background

current and time are selected in order to allow solidification of metal between

pulses. This current is used in welding of stainless steels.

High-frequency pulsed current (5-30 kHz) improves arc stiffness, increasing

penetration depth and maximum welding speed and decreasing formation of

porosity in the weld metal. This current is advantageous in automatic welding

applications.