Page 52 - Welding Robots Technology, System Issues, and Applications

P. 52

gas

unit

regulator Feed current Welding Technology 37

filler wire

weld torch

gas nozzle

contact

GMAW tube

power

source filler wire

base metal

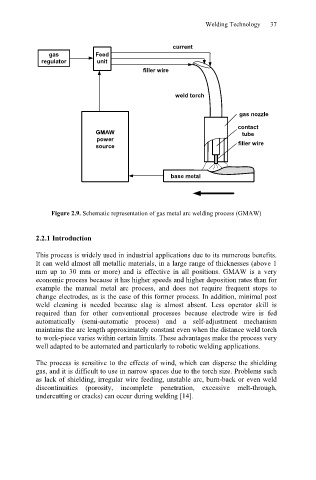

Figure 2.9. Schematic representation of gas metal arc welding process (GMAW)

2.2.1 Introduction

This process is widely used in industrial applications due to its numerous benefits.

It can weld almost all metallic materials, in a large range of thicknesses (above 1

mm up to 30 mm or more) and is effective in all positions. GMAW is a very

economic process because it has higher speeds and higher deposition rates than for

example the manual metal arc process, and does not require frequent stops to

change electrodes, as is the case of this former process. In addition, minimal post

weld cleaning is needed because slag is almost absent. Less operator skill is

required than for other conventional processes because electrode wire is fed

automatically (semi-automatic process) and a self-adjustment mechanism

maintains the arc length approximately constant even when the distance weld torch

to work-piece varies within certain limits. These advantages make the process very

well adapted to be automated and particularly to robotic welding applications.

The process is sensitive to the effects of wind, which can disperse the shielding

gas, and it is difficult to use in narrow spaces due to the torch size. Problems such

as lack of shielding, irregular wire feeding, unstable arc, burn-back or even weld

discontinuities (porosity, incomplete penetration, excessive melt-through,

undercutting or cracks) can occur during welding [14].