Page 63 - Welding Robots Technology, System Issues, and Applications

P. 63

Welding Robots

48

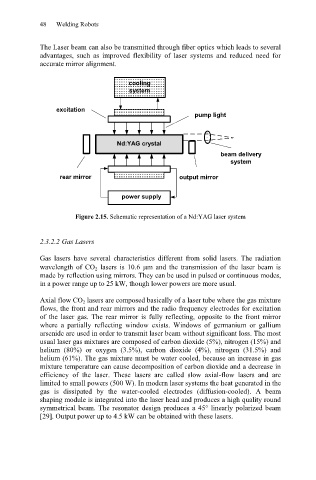

The Laser beam can also be transmitted through fiber optics which leads to several

advantages, such as improved flexibility of laser systems and reduced need for

accurate mirror alignment.

cooling

system

excitation

pump light

Nd:YAG crystal

beam delivery

system

rear mirror output mirror

power supply

Figure 2.15. Schematic representation of a Nd:YAG laser system

2.3.2.2 Gas Lasers

Gas lasers have several characteristics different from solid lasers. The radiation

wavelength of CO 2 lasers is 10.6 Pm and the transmission of the laser beam is

made by reflection using mirrors. They can be used in pulsed or continuous modes,

in a power range up to 25 kW, though lower powers are more usual.

Axial flow CO 2 lasers are composed basically of a laser tube where the gas mixture

flows, the front and rear mirrors and the radio frequency electrodes for excitation

of the laser gas. The rear mirror is fully reflecting, opposite to the front mirror

where a partially reflecting window exists. Windows of germanium or gallium

arsenide are used in order to transmit laser beam without significant loss. The most

usual laser gas mixtures are composed of carbon dioxide (5%), nitrogen (15%) and

helium (80%) or oxygen (3.5%), carbon dioxide (4%), nitrogen (31.5%) and

helium (61%). The gas mixture must be water cooled, because an increase in gas

mixture temperature can cause decomposition of carbon dioxide and a decrease in

efficiency of the laser. These lasers are called slow axial-flow lasers and are

limited to small powers (500 W). In modern laser systems the heat generated in the

gas is dissipated by the water-cooled electrodes (diffusion-cooled). A beam

shaping module is integrated into the laser head and produces a high quality round

symmetrical beam. The resonator design produces a 45° linearly polarized beam

[29]. Output power up to 4.5 kW can be obtained with these lasers.