Page 64 - Welding Robots Technology, System Issues, and Applications

P. 64

Welding Technology

heat

system

exchanger cooling tangential blower 49

laser beam

output window

rear mirror

HF electrodes power supply output mirror

gas flow direction

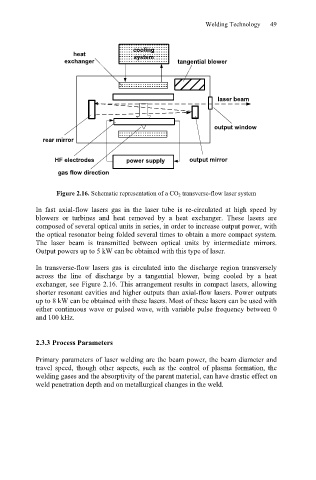

Figure 2.16. Schematic representation of a CO 2 transverse-flow laser system

In fast axial-flow lasers gas in the laser tube is re-circulated at high speed by

blowers or turbines and heat removed by a heat exchanger. These lasers are

composed of several optical units in series, in order to increase output power, with

the optical resonator being folded several times to obtain a more compact system.

The laser beam is transmitted between optical units by intermediate mirrors.

Output powers up to 5 kW can be obtained with this type of laser.

In transverse-flow lasers gas is circulated into the discharge region transversely

across the line of discharge by a tangential blower, being cooled by a heat

exchanger, see Figure 2.16. This arrangement results in compact lasers, allowing

shorter resonant cavities and higher outputs than axial-flow lasers. Power outputs

up to 8 kW can be obtained with these lasers. Most of these lasers can be used with

either continuous wave or pulsed wave, with variable pulse frequency between 0

and 100 kHz.

2.3.3 Process Parameters

Primary parameters of laser welding are the beam power, the beam diameter and

travel speed, though other aspects, such as the control of plasma formation, the

welding gases and the absorptivity of the parent material, can have drastic effect on

weld penetration depth and on metallurgical changes in the weld.