Page 76 - Welding Robots Technology, System Issues, and Applications

P. 76

61

Welding Technology

2.4.4 Process Variants

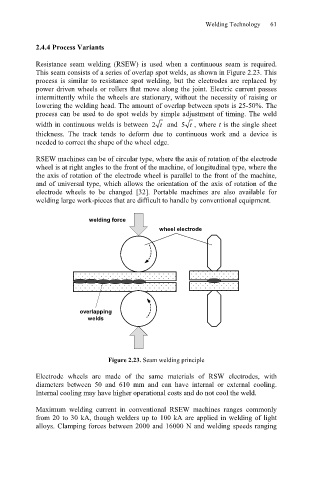

Resistance seam welding (RSEW) is used when a continuous seam is required.

This seam consists of a series of overlap spot welds, as shown in Figure 2.23. This

process is similar to resistance spot welding, but the electrodes are replaced by

power driven wheels or rollers that move along the joint. Electric current passes

intermittently while the wheels are stationary, without the necessity of raising or

lowering the welding head. The amount of overlap between spots is 25-50%. The

process can be used to do spot welds by simple adjustment of timing. The weld

width in continuous welds is between 2 t and 5 t , where t is the single sheet

thickness. The track tends to deform due to continuous work and a device is

needed to correct the shape of the wheel edge.

RSEW machines can be of circular type, where the axis of rotation of the electrode

wheel is at right angles to the front of the machine, of longitudinal type, where the

the axis of rotation of the electrode wheel is parallel to the front of the machine,

and of universal type, which allows the orientation of the axis of rotation of the

electrode wheels to be changed [32]. Portable machines are also available for

welding large work-pieces that are difficult to handle by conventional equipment.

welding force

wheel electrode

overlapping

welds

Figure 2.23. Seam welding principle

Electrode wheels are made of the same materials of RSW electrodes, with

diameters between 50 and 610 mm and can have internal or external cooling.

Internal cooling may have higher operational costs and do not cool the weld.

Maximum welding current in conventional RSEW machines ranges commonly

from 20 to 30 kA, though welders up to 100 kA are applied in welding of light

alloys. Clamping forces between 2000 and 16000 N and welding speeds ranging