Page 78 - Welding Robots Technology, System Issues, and Applications

P. 78

63

Welding Technology

2.5.1 Introduction

This welding process leads to the appearance of a thermo-mechanically affected

zone (TMAZ), which results from both plastic deformation and thermal exposure

of the material, and of a heat affected zone (HAZ), which only suffers the effect of

the thermal cycle. In the central part of the TMAZ there usually appears a distinct

nugget, having an onion ring feature, attributed to dynamic re-crystallization or

dynamic recovery of the microstructure [44].

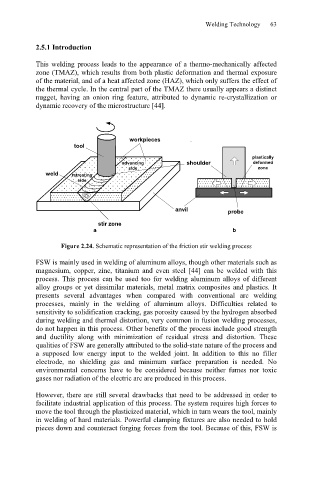

workpieces

tool

plastically

advancing shoulder deformed

side zone

weld retreating

side

anvil probe

stir zone

a b

Figure 2.24. Schematic representation of the friction stir welding process

FSW is mainly used in welding of aluminum alloys, though other materials such as

magnesium, copper, zinc, titanium and even steel [44] can be welded with this

process. This process can be used too for welding aluminum alloys of different

alloy groups or yet dissimilar materials, metal matrix composites and plastics. It

presents several advantages when compared with conventional arc welding

processes, mainly in the welding of aluminum alloys. Difficulties related to

sensitivity to solidification cracking, gas porosity caused by the hydrogen absorbed

during welding and thermal distortion, very common in fusion welding processes,

do not happen in this process. Other benefits of the process include good strength

and ductility along with minimization of residual stress and distortion. These

qualities of FSW are generally attributed to the solid-state nature of the process and

a supposed low energy input to the welded joint. In addition to this no filler

electrode, no shielding gas and minimum surface preparation is needed. No

environmental concerns have to be considered because neither fumes nor toxic

gases nor radiation of the electric arc are produced in this process.

However, there are still several drawbacks that need to be addressed in order to

facilitate industrial application of this process. The system requires high forces to

move the tool through the plasticized material, which in turn wears the tool, mainly

in welding of hard materials. Powerful clamping fixtures are also needed to hold

pieces down and counteract forging forces from the tool. Because of this, FSW is