Page 80 - Welding Robots Technology, System Issues, and Applications

P. 80

Welding Technology

65

a) b) c)

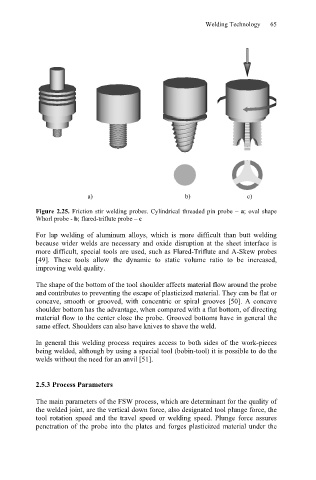

Figure 2.25. Friction stir welding probes. Cylindrical threaded pin probe – a; oval shape

Whorl probe - b; flared-triflute probe – c

For lap welding of aluminum alloys, which is more difficult than butt welding

because wider welds are necessary and oxide disruption at the sheet interface is

more difficult, special tools are used, such as Flared-Triflute and A-Skew probes

[49]. These tools allow the dynamic to static volume ratio to be increased,

improving weld quality.

The shape of the bottom of the tool shoulder affects material flow around the probe

and contributes to preventing the escape of plasticized material. They can be flat or

concave, smooth or grooved, with concentric or spiral grooves [50]. A concave

shoulder bottom has the advantage, when compared with a flat bottom, of directing

material flow to the center close the probe. Grooved bottoms have in general the

same effect. Shoulders can also have knives to shave the weld.

In general this welding process requires access to both sides of the work-pieces

being welded, although by using a special tool (bobin-tool) it is possible to do the

welds without the need for an anvil [51].

2.5.3 Process Parameters

The main parameters of the FSW process, which are determinant for the quality of

the welded joint, are the vertical down force, also designated tool plunge force, the

tool rotation speed and the travel speed or welding speed. Plunge force assures

penetration of the probe into the plates and forges plasticized material under the