Page 178 - Well Control for Completions and Interventions

P. 178

170 Well Control for Completions and Interventions

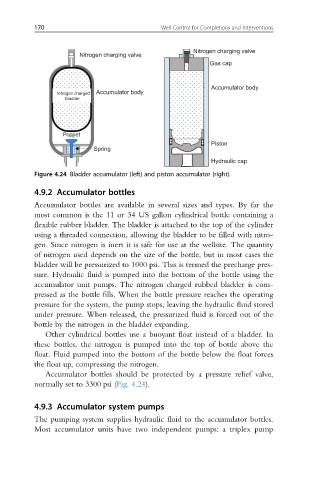

Nitrogen charging valve

Nitrogen charging valve

Gas cap

Accumulator body

Nitrogen charged Accumulator body

bladder

Poppet

Piston

Spring

Hydraulic cap

Figure 4.24 Bladder accumulator (left) and piston accumulator (right).

4.9.2 Accumulator bottles

Accumulator bottles are available in several sizes and types. By far the

most common is the 11 or 34 US gallon cylindrical bottle containing a

flexible rubber bladder. The bladder is attached to the top of the cylinder

using a threaded connection, allowing the bladder to be filled with nitro-

gen. Since nitrogen is inert it is safe for use at the wellsite. The quantity

of nitrogen used depends on the size of the bottle, but in most cases the

bladder will be pressurized to 1000 psi. This is termed the precharge pres-

sure. Hydraulic fluid is pumped into the bottom of the bottle using the

accumulator unit pumps. The nitrogen charged rubbed bladder is com-

pressed as the bottle fills. When the bottle pressure reaches the operating

pressure for the system, the pump stops, leaving the hydraulic fluid stored

under pressure. When released, the pressurized fluid is forced out of the

bottle by the nitrogen in the bladder expanding.

Other cylindrical bottles use a buoyant float instead of a bladder. In

these bottles, the nitrogen is pumped into the top of bottle above the

float. Fluid pumped into the bottom of the bottle below the float forces

the float up, compressing the nitrogen.

Accumulator bottles should be protected by a pressure relief valve,

normally set to 3300 psi (Fig. 4.24).

4.9.3 Accumulator system pumps

The pumping system supplies hydraulic fluid to the accumulator bottles.

Most accumulator units have two independent pumps: a triplex pump