Page 99 - Well Control for Completions and Interventions

P. 99

Completion Equipment 91

Intermediate (B) annulus: One outlet should have a single gate valve

with a sampling/bleed down arrangement. The other side may be termi-

nated with a flange, needle valve, and pressure gauge.

Outer (C) annulus: One outlet should have a single gate valve with a

sampling/bleed down arrangement. The other side may be terminated

with a flange, needle valve, and pressure gauge. When there are more

than three annuli on the wellhead, these should be treated in the same

way as the “C” annulus.

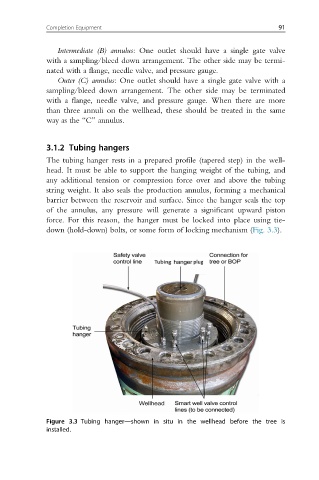

3.1.2 Tubing hangers

The tubing hanger rests in a prepared profile (tapered step) in the well-

head. It must be able to support the hanging weight of the tubing, and

any additional tension or compression force over and above the tubing

string weight. It also seals the production annulus, forming a mechanical

barrier between the reservoir and surface. Since the hanger seals the top

of the annulus, any pressure will generate a significant upward piston

force. For this reason, the hanger must be locked into place using tie-

down (hold-down) bolts, or some form of locking mechanism (Fig. 3.3).

Figure 3.3 Tubing hanger—shown in situ in the wellhead before the tree is

installed.