Page 390 - Wind Energy Handbook

P. 390

364 CONCEPTUAL DESIGN OF HORIZONTAL-AXIS TURBINES

6.10 Type of Generator

Fixed-speed wind turbines differ from almost all conventional generating plant by

using induction rather than synchronous generators. This choice is driven by the

requirement for significant damping in the drive train due to the cyclic variations in

the torque developed by the aerodynamic rotor.

Both synchronous and induction generators have similar winding arrangements

on the stator which, when connected to the three-phase network voltage, produce a

fixed-speed, rotating magnetic field. However, the rotors of the two machines are

quite different (Hindmarsh, 1984, McPherson, 1990). A synchronous machine has

magnets mounted on its rotor and the rotor magnetic field then locks into that

produced by the stator leading to operation at synchronous speed. For power

generation applications, electromagnets are used on the rotor excited by an

externally applied direct current. Although the rotor operates at the same speed as

the stator magnetic field it leads the stator field by an angle depending on the

applied torque. In contrast, the rotor of a conventional induction machine has a

‘squirrel cage’ winding into which currents are induced as the rotor bars cut the

magnetic field produced by the stator. Hence, an induction generator can only

develop torque at a rotational speed slightly greater than that of the stator field.

This ‘slip speed’ is proportional to the applied torque.

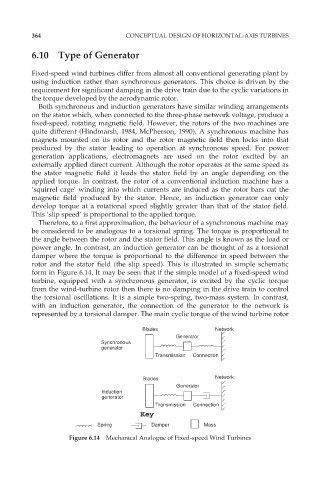

Therefore, to a first approximation, the behaviour of a synchronous machine may

be considered to be analogous to a torsional spring. The torque is proportional to

the angle between the rotor and the stator field. This angle is known as the load or

power angle. In contrast, an induction generator can be thought of as a torsional

damper where the torque is proportional to the difference in speed between the

rotor and the stator field (the slip speed). This is illustrated in simple schematic

form in Figure 6.14. It may be seen that if the simple model of a fixed-speed wind

turbine, equipped with a synchronous generator, is excited by the cyclic torque

from the wind-turbine rotor then there is no damping in the drive train to control

the torsional oscillations. It is a simple two-spring, two-mass system. In contrast,

with an induction generator, the connection of the generator to the network is

represented by a torsional damper. The main cyclic torque of the wind turbine rotor

Blades Network

Generator

Synchronous

generator

Transmission Connection

Blades Network

Generator

Induction

generator

Transmission Connection

Key

Spring Damper Mass

Figure 6.14 Mechanical Analogue of Fixed-speed Wind Turbines