Page 393 - Wind Energy Handbook

P. 393

DRIVE-TRAIN MOUNTING ARRANGEMENT OPTIONS 367

Front- Rear- Gearbox reaction arm

bearing bearing

housing housing

Gearbox

Rotor

brake

Rotor hub

Generator

Low-speed shaft

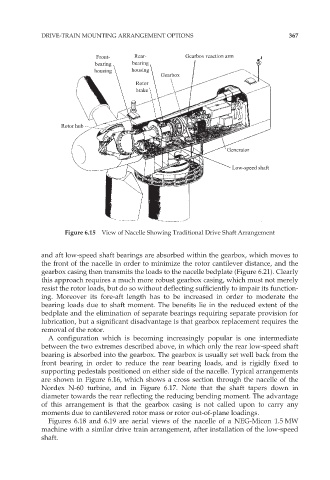

Figure 6.15 View of Nacelle Showing Traditional Drive Shaft Arrangement

and aft low-speed shaft bearings are absorbed within the gearbox, which moves to

the front of the nacelle in order to minimize the rotor cantilever distance, and the

gearbox casing then transmits the loads to the nacelle bedplate (Figure 6.21). Clearly

this approach requires a much more robust gearbox casing, which must not merely

resist the rotor loads, but do so without deflecting sufficiently to impair its function-

ing. Moreover its fore-aft length has to be increased in order to moderate the

bearing loads due to shaft moment. The benefits lie in the reduced extent of the

bedplate and the elimination of separate bearings requiring separate provision for

lubrication, but a significant disadvantage is that gearbox replacement requires the

removal of the rotor.

A configuration which is becoming increasingly popular is one intermediate

between the two extremes described above, in which only the rear low-speed shaft

bearing is absorbed into the gearbox. The gearbox is usually set well back from the

front bearing in order to reduce the rear bearing loads, and is rigidly fixed to

supporting pedestals positioned on either side of the nacelle. Typical arrangements

are shown in Figure 6.16, which shows a cross section through the nacelle of the

Nordex N-60 turbine, and in Figure 6.17. Note that the shaft tapers down in

diameter towards the rear reflecting the reducing bending moment. The advantage

of this arrangement is that the gearbox casing is not called upon to carry any

moments due to cantilevered rotor mass or rotor out-of-plane loadings.

Figures 6.18 and 6.19 are aerial views of the nacelle of a NEG-Micon 1.5 MW

machine with a similar drive train arrangement, after installation of the low-speed

shaft.