Page 427 - Wind Energy Handbook

P. 427

BLADES 401

45

40

35 Rotational speed = 17 r.p.m. intensity = 15%,

Percentage contribution per 2 m/s bin 25 16.10% intensity, m = 10

No. of blades = 3

Turbulence

Rotor diameter = 64 m

m = 12

30

Turbulence

intensity = 15%,

m = 10

20

IEC turbulence

15

10 17%

21%

5

0

0 5 10 15 20 25 30

Mean wind speed (m/s)

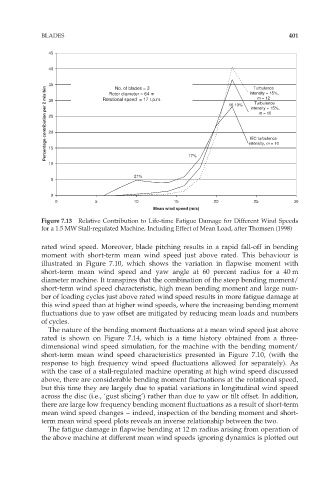

Figure 7.13 Relative Contribution to Life-time Fatigue Damage for Different Wind Speeds

for a 1.5 MW Stall-regulated Machine, Including Effect of Mean Load, after Thomsen (1998)

rated wind speed. Moreover, blade pitching results in a rapid fall-off in bending

moment with short-term mean wind speed just above rated. This behaviour is

illustrated in Figure 7.10, which shows the variation in flapwise moment with

short-term mean wind speed and yaw angle at 60 percent radius for a 40 m

diameter machine. It transpires that the combination of the steep bending moment/

short-term wind speed characteristic, high mean bending moment and large num-

ber of loading cycles just above rated wind speed results in more fatigue damage at

this wind speed than at higher wind speeds, where the increasing bending moment

fluctuations due to yaw offset are mitigated by reducing mean loads and numbers

of cycles.

The nature of the bending moment fluctuations at a mean wind speed just above

rated is shown on Figure 7.14, which is a time history obtained from a three-

dimensional wind speed simulation, for the machine with the bending moment/

short-term mean wind speed characteristics presented in Figure 7.10, (with the

response to high frequency wind speed fluctuations allowed for separately). As

with the case of a stall-regulated machine operating at high wind speed discussed

above, there are considerable bending moment fluctuations at the rotational speed,

but this time they are largely due to spatial variations in longitudinal wind speed

across the disc (i.e., ‘gust slicing’) rather than due to yaw or tilt offset. In addition,

there are large low frequency bending moment fluctuations as a result of short-term

mean wind speed changes – indeed, inspection of the bending moment and short-

term mean wind speed plots reveals an inverse relationship between the two.

The fatigue damage in flapwise bending at 12 m radius arising from operation of

the above machine at different mean wind speeds ignoring dynamics is plotted out