Page 176 - Wire Bonding in Microelectronics

P. 176

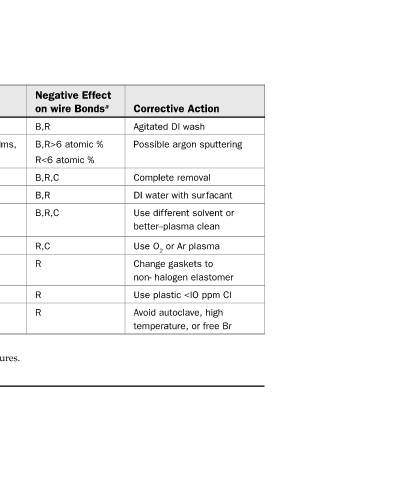

Corrective Action Agitated DI wash Possible argon sputtering Complete removal DI water with surfacant Use different solvent or better--plasma clean Use O 2 or Ar plasma Change gaskets to non- halogen elastomer Use plastic <IO ppm Cl Avoid autoclave, high temperature, or free Br

Negative Effect on wire Bonds a B,R B,R>6 atomic % R<6 atomic % B,R,C B,R B,R,C R,C R R R

Contributing Causes Static DI wash May leave fluorocarbon polymer films, F or Cl Dichlorobenzene residue Cl in water Water contamination releases HCI Autoclave Copper-bonded gold thick film, surface Cu-->CuCI 2 (Al wire bonds) 85°C/85% RH, autoclave High temp (175–200°C) or 125°C

Source of Contamination Silox etch (Fluoride) F or Cl residue on pads from RIE Photo resist stripper Wafer sawing in city water Trichlorethane (TCA) CF4/0 2 plasma clean Cl from burn-in oven chloroprene gasket Cl from plastic Br from encapsulation fire retardant See Refs. [5

152