Page 48 - Wire Bonding in Microelectronics

P. 48

Ultrasonic Bonding Systems and Technologies 27

6 6

Aluminum Aluminum

18°C 18°C

5 2 5

Stress (kg/mm 2 ) 4 18 W/cm 18°C 4 200°C

3

3

2

35 W/cm 2 2 400°C

1 18°C 1

50 W/cm 2

18°C 600°C

0 0

20 60 100 20 60 100

Elongation (%)

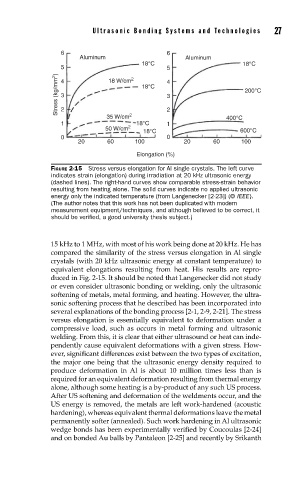

FIGURE 2-15 Stress versus elongation for Al single crystals. The left curve

indicates strain (elongation) during irradiation at 20 kHz ultrasonic energy

(dashed lines). The right-hand curves show comparable stress-strain behavior

resulting from heating alone. The solid curves indicate no applied ultrasonic

energy only the indicated temperature (from Langenecker [2-23]) (© IEEE).

(The author notes that this work has not been duplicated with modern

measurement equipment/techniques, and although believed to be correct, it

should be verifi ed, a good university thesis subject.)

15 kHz to 1 MHz, with most of his work being done at 20 kHz. He has

compared the similarity of the stress versus elongation in Al single

crystals (with 20 kHz ultrasonic energy at constant temperature) to

equivalent elongations resulting from heat. His results are repro-

duced in Fig. 2-15. It should be noted that Langenecker did not study

or even consider ultrasonic bonding or welding, only the ultrasonic

softening of metals, metal forming, and heating. However, the ultra-

sonic softening process that he described has been incorporated into

several explanations of the bonding process [2-1, 2-9, 2-21]. The stress

versus elongation is essentially equivalent to deformation under a

compressive load, such as occurs in metal forming and ultrasonic

welding. From this, it is clear that either ultrasound or heat can inde-

pendently cause equivalent deformations with a given stress. How-

ever, significant differences exist between the two types of excitation,

the major one being that the ultrasonic energy density required to

produce deformation in Al is about 10 million times less than is

required for an equivalent deformation resulting from thermal energy

alone, although some heating is a by-product of any such US process.

After US softening and deformation of the weldments occur, and the

US energy is removed, the metals are left work-hardened (acoustic

hardening), whereas equivalent thermal deformations leave the metal

permanently softer (annealed). Such work hardening in Al ultrasonic

wedge bonds has been experimentally verified by Coucoulas [2-24]

and on bonded Au balls by Pantaleon [2-25] and recently by Srikanth