Page 46 - Wire Bonding in Microelectronics

P. 46

Ultrasonic Bonding Systems and Technologies 25

after 2 ms after 4 ms

(a) (b)

after 6 ms after 16 ms

(c) (d)

(e)

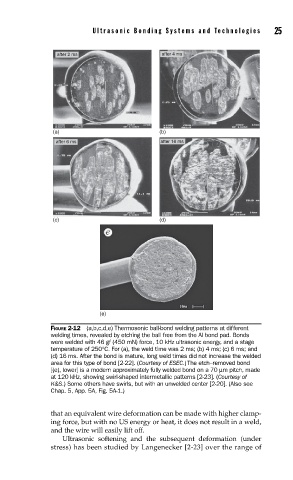

FIGURE 2-12 (a,b,c,d,e) Thermosonic ball-bond welding patterns at different

welding times, revealed by etching the ball free from the Al bond pad. Bonds

were welded with 46 gf (450 mN) force, 10 kHz ultrasonic energy, and a stage

temperature of 250°C. For (a), the weld time was 2 ms; (b) 4 ms; (c) 6 ms; and

(d) 16 ms. After the bond is mature, long weld times did not increase the welded

area for this type of bond [2-22]. (Courtesy of ESEC.)The etch–removed bond

[(e), lower] is a modern approximately fully welded bond on a 70 µm pitch, made

at 120 kHz, showing swirl-shaped intermetallic patterns [2-23]. (Courtesy of

K&S.) Some others have swirls, but with an unwelded center [2-20]. (Also see

Chap. 5, App. 5A, Fig. 5A-1.)

that an equivalent wire deformation can be made with higher clamp-

ing force, but with no US energy or heat, it does not result in a weld,

and the wire will easily lift off.

Ultrasonic softening and the subsequent deformation (under

stress) has been studied by Langenecker [2-23] over the range of