Page 131 - Mechanical Behavior of Materials

P. 131

132 Chapter 4 Mechanical Testing: Tension Test and Other Basic Tests

σ σ

x

x

L

i

ΔL ΔL

L i

d L i

i

d min

ΔL

0

(a) ε

x

(b)

0

ε

(c) x

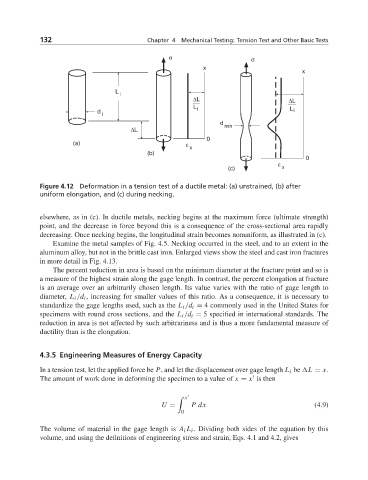

Figure 4.12 Deformation in a tension test of a ductile metal: (a) unstrained, (b) after

uniform elongation, and (c) during necking.

elsewhere, as in (c). In ductile metals, necking begins at the maximum force (ultimate strength)

point, and the decrease in force beyond this is a consequence of the cross-sectional area rapidly

decreasing. Once necking begins, the longitudinal strain becomes nonuniform, as illustrated in (c).

Examine the metal samples of Fig. 4.5. Necking occurred in the steel, and to an extent in the

aluminum alloy, but not in the brittle cast iron. Enlarged views show the steel and cast iron fractures

in more detail in Fig. 4.13.

The percent reduction in area is based on the minimum diameter at the fracture point and so is

a measure of the highest strain along the gage length. In contrast, the percent elongation at fracture

is an average over an arbitrarily chosen length. Its value varies with the ratio of gage length to

diameter, L i /d i , increasing for smaller values of this ratio. As a consequence, it is necessary to

standardize the gage lengths used, such as the L i /d i = 4 commonly used in the United States for

specimens with round cross sections, and the L i /d i = 5 specified in international standards. The

reduction in area is not affected by such arbitrariness and is thus a more fundamental measure of

ductility than is the elongation.

4.3.5 Engineering Measures of Energy Capacity

In a tension test, let the applied force be P, and let the displacement over gage length L i be L = x.

The amount of work done in deforming the specimen to a value of x = x is then

x

U = Pdx (4.9)

0

The volume of material in the gage length is A i L i . Dividing both sides of the equation by this

volume, and using the definitions of engineering stress and strain, Eqs. 4.1 and 4.2, gives