Page 405 - Mechanical Behavior of Materials

P. 405

406 Chapter 8 Fracture of Cracked Members

t

2a

crack r avg

pressure

Figure P8.19

The material is titanium 6Al-4V alloy (annealed), the pressure is p = 40 MPa, and the tube

dimensions are r avg = 50 and t = 4 mm. A crack of tip-to-tip length 2a = 20 mm may be

present. What is the safety factor against fracture? What is the safety factor against yielding

with no crack present? Is the tube safe to use if failure could present a safety hazard?

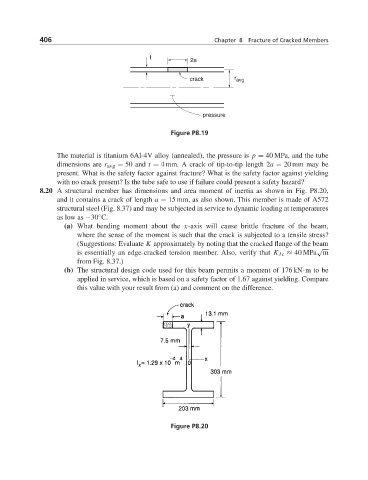

8.20 A structural member has dimensions and area moment of inertia as shown in Fig. P8.20,

and it contains a crack of length a = 15 mm, as also shown. This member is made of A572

structural steel (Fig. 8.37) and may be subjected in service to dynamic loading at temperatures

◦

as low as −30 C.

(a) What bending moment about the x-axis will cause brittle fracture of the beam,

where the sense of the moment is such that the crack is subjected to a tensile stress?

(Suggestions: Evaluate K approximately by noting that the cracked flange of the beam

√

is essentially an edge-cracked tension member. Also, verify that K Ic ≈ 40 MPa m

from Fig. 8.37.)

(b) The structural design code used for this beam permits a moment of 176 kN·mtobe

applied in service, which is based on a safety factor of 1.67 against yielding. Compare

this value with your result from (a) and comment on the difference.

Figure P8.20