Page 410 - Mechanical Behavior of Materials

P. 410

Problems and Questions 411

Section 8.6

8.37 Assume that each of the rotor steels of Fig. 8.35 except A217 is being considered for use

at room temperature (22 C). The design will be such that the highest stress does not exceed

◦

half of the respective yield strength in each case. Assuming a flaw geometry that is a half-

circular surface crack in a semi-infinite body, determine the largest permissible crack size a

for each material if a safety factor of 2.0 against brittle fracture is required. Also comment on

how this information might affect the choice among these steels.

8.38 A bending member has dimensions, as defined in Fig. 8.13(a), of width b = 50 mm and

thickness t = 20 mm. A through-thickness crack in the edge subjected to tension stress may

be as long as a = 10 mm. What moment is expected to cause failure if the material is AISI

4340 steel (Fig. 8.32) with a yield strength of (a) 800 MPa and (b) 1600 MPa? In each

case, consider both brittle fracture and fully plastic yielding as possible failure modes. Then

(c) comment on whether or not it is beneficial to use the higher strength steel in this case.

(Look at Prob. 8.42 for tabulated values from Fig. 8.32.)

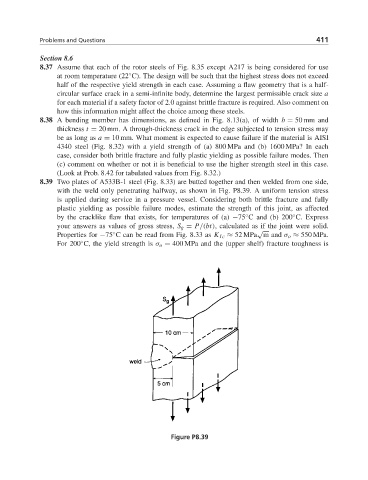

8.39 Two plates of A533B-1 steel (Fig. 8.33) are butted together and then welded from one side,

with the weld only penetrating halfway, as shown in Fig. P8.39. A uniform tension stress

is applied during service in a pressure vessel. Considering both brittle fracture and fully

plastic yielding as possible failure modes, estimate the strength of this joint, as affected

◦

by the cracklike flaw that exists, for temperatures of (a) −75 C and (b) 200 C. Express

◦

your answers as values of gross stress, S g = P/(bt), calculated as if the joint were solid.

√

Properties for −75 C can be read from Fig. 8.33 as K Ic ≈ 52 MPa m and σ o ≈ 550 MPa.

◦

For 200 C, the yield strength is σ o = 400 MPa and the (upper shelf) fracture toughness is

◦

Figure P8.39