Page 406 - Mechanical Behavior of Materials

P. 406

Problems and Questions 407

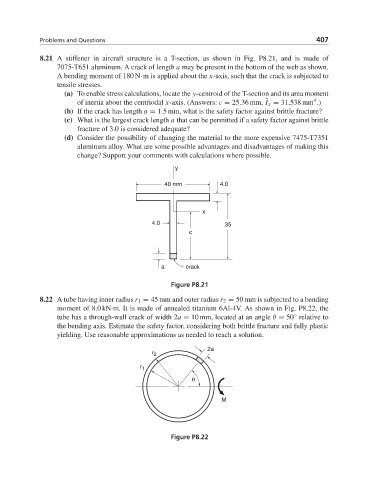

8.21 A stiffener in aircraft structure is a T-section, as shown in Fig. P8.21, and is made of

7075-T651 aluminum. A crack of length a may be present in the bottom of the web as shown.

A bending moment of 180 N·m is applied about the x-axis, such that the crack is subjected to

tensile stresses.

(a) To enable stress calculations, locate the y-centroid of the T-section and its area moment

4

of inertia about the centriodal x-axis. (Answers: c = 25.36 mm, I x = 31,538 mm .)

¯

(b) If the crack has length a = 1.5 mm, what is the safety factor against brittle fracture?

(c) What is the largest crack length a that can be permitted if a safety factor against brittle

fracture of 3.0 is considered adequate?

(d) Consider the possibility of changing the material to the more expensive 7475-T7351

aluminum alloy. What are some possible advantages and disadvantages of making this

change? Support your comments with calculations where possible.

y

40 mm 4.0

x

4.0 35

c

a crack

Figure P8.21

8.22 A tube having inner radius r 1 = 45 mm and outer radius r 2 = 50 mm is subjected to a bending

moment of 8.0 kN·m. It is made of annealed titanium 6Al-4V. As shown in Fig. P8.22, the

tube has a through-wall crack of width 2a = 10 mm, located at an angle θ = 50 relative to

◦

the bending axis. Estimate the safety factor, considering both brittle fracture and fully plastic

yielding. Use reasonable approximations as needed to reach a solution.

2a

r 2

r 1

θ

M

Figure P8.22