Page 157 - Materials Chemistry, Second Edition

P. 157

142 A. Bjørn et al.

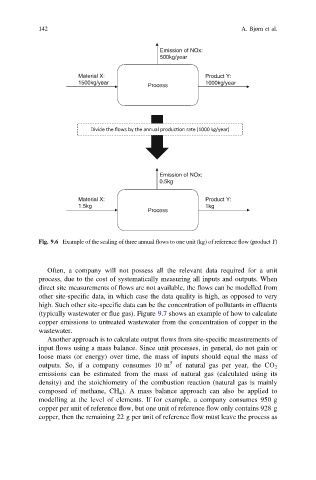

Emission of NOx:

500kg/year

Material X: Product Y:

1500kg/year 1000kg/year

Process

Divide the flows by the annual producƟon rate (1000 kg/year)

Emission of NOx:

0.5kg

Material X: Product Y:

1.5kg 1kg

Process

Fig. 9.6 Example of the scaling of three annual flows to one unit (kg) of reference flow (product Y)

Often, a company will not possess all the relevant data required for a unit

process, due to the cost of systematically measuring all inputs and outputs. When

direct site measurements of flows are not available, the flows can be modelled from

other site-specific data, in which case the data quality is high, as opposed to very

high. Such other site-specific data can be the concentration of pollutants in effluents

(typically wastewater or flue gas). Figure 9.7 shows an example of how to calculate

copper emissions to untreated wastewater from the concentration of copper in the

wastewater.

Another approach is to calculate output flows from site-specific measurements of

input flows using a mass balance. Since unit processes, in general, do not gain or

loose mass (or energy) over time, the mass of inputs should equal the mass of

3

outputs. So, if a company consumes 10 m of natural gas per year, the CO 2

emissions can be estimated from the mass of natural gas (calculated using its

density) and the stoichiometry of the combustion reaction (natural gas is mainly

composed of methane, CH 4 ). A mass balance approach can also be applied to

modelling at the level of elements. If for example, a company consumes 950 g

copper per unit of reference flow, but one unit of reference flow only contains 928 g

copper, then the remaining 22 g per unit of reference flow must leave the process as