Page 141 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 141

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap11 Final Proof page 136 3.1.2007 8:54pm Compositor Name: SJoearun

11/136 EQUIPMENT DESIGN AND SELECTION

so 11.3 Compressors

PQ th When natural gas does not have sufficient potential energy

HP i ¼ : (11:25)

33,000e m to flow, a compressor station is needed. Five types of

compressor stations are generally used in the natural gas

The usual form of this equation is in p (psi) and q (gal/ production industry:

min):

2

p(12) [q(0:1337)] . Field gas-gathering stations to gather gas from wells in

HP i ¼ , (11:26)

33,000e m which pressure is insufficient to produce at a desired rate

of flow into a transmission or distribution system. These

that is,

stations generally handle suction pressures from below

pq

HP i ¼ : (11:27) atmospheric pressure to 750 psig and volumes from a

1714e m few thousand to many million cubic feet per day.

The other form of this equation is in p (psi) and q o (bbl/ . Relay or main-line stations to boost pressure in trans-

day) for oil transportation: mission lines compress generally large volumes of gas at

a pressure range between 200 and 1,300 psig.

pq o

HP i ¼ : (11:28) . Re-pressuring or recycling stations to provide gas pres-

58,766e m

sures as high as 6,000 psig for processing or secondary

Equations (11.27) and (11.28) are valid for any type of oil recovery projects.

pump. . Storage field stations to compress trunk line gas for

injection into storage wells at pressures up to 4,000 psig.

Example Problem 11.1 A pipeline transporting 5,000 bbl/ . Distribution plant stations to pump gas from holder

day of oil requires a pump with a minimum output supply to medium- or high-pressure distribution lines

pressure of 1,000 psi. The available suction pressure is at about 20–100 psig, or pump into bottle storage up

300 psi. Select a triplex pump for this operation. to 2,500 psig.

Solution Assuming a mechanical efficient of 0.85, the

horsepower requirement is 11.3.1 Types of Compressors

The compressors used in today’s natural gas production

pq o (1,000)(5,000) industry fall into two distinct types: reciprocating and

HP i ¼ ¼ ¼ 100 hp: rotary compressors. Reciprocating compressors are most

58,766e m 58,766(0:85)

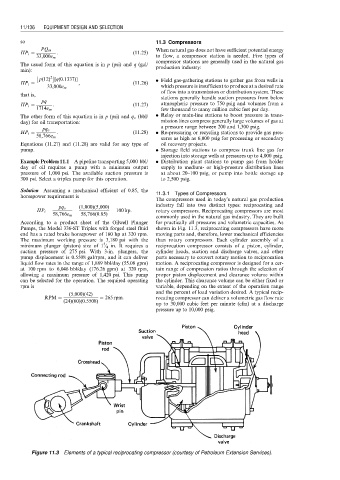

commonly used in the natural gas industry. They are built

According to a product sheet of the Oilwell Plunger for practically all pressures and volumetric capacities. As

Pumps, the Model 336-ST Triplex with forged steel fluid shown in Fig. 11.3, reciprocating compressors have more

end has a rated brake horsepower of 160 hp at 320 rpm. moving parts and, therefore, lower mechanical efficiencies

The maximum working pressure is 3,180 psi with the than rotary compressors. Each cylinder assembly of a

3

minimum plunger (piston) size of 1 ⁄ 4 in. It requires a reciprocation compressor consists of a piston, cylinder,

suction pressure of 275 psi. With 3-in. plungers, the cylinder heads, suction and discharge valves, and other

pump displacement is 0.5508 gal/rpm, and it can deliver parts necessary to convert rotary motion to reciprocation

liquid flow rates in the range of 1,889 bbl/day (55.08 gpm) motion. A reciprocating compressor is designed for a cer-

at 100 rpm to 6,046 bbl/day (176.26 gpm) at 320 rpm, tain range of compression ratios through the selection of

allowing a maximum pressure of 1,420 psi. This pump proper piston displacement and clearance volume within

can be selected for the operation. The required operating the cylinder. This clearance volume can be either fixed or

rpm is variable, depending on the extent of the operation range

and the percent of load variation desired. A typical recip-

(5,000)(42)

RPM ¼ ¼ 265 rpm: rocating compressor can deliver a volumetric gas flow rate

(24)(60)(0:5508)

up to 30,000 cubic feet per minute (cfm) at a discharge

pressure up to 10,000 psig.

Figure 11.3 Elements of a typical reciprocating compressor (courtesy of Petroleum Extension Services).