Page 146 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 146

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap11 Final Proof page 141 3.1.2007 8:54pm Compositor Name: SJoearun

TRANSPORTATION SYSTEMS 11/141

0.80

Gasoline

Propane/butane

0.75 Diesel

Fuel Consumption (lbs/hp-hr) 0.65

0.70

0.60

0.55

0.50

50 60 70 80 90 100

% Load on Prime Mover

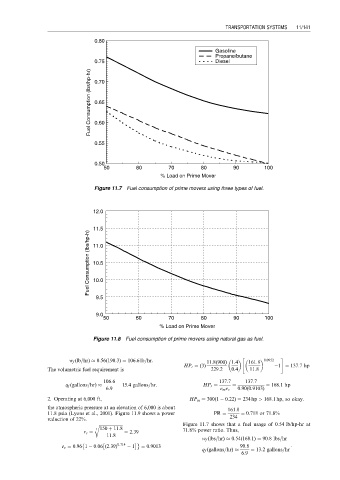

Figure 11.7 Fuel consumption of prime movers using three types of fuel.

12.0

11.5

Fuel Consumption (lbs/hp-h) 11.0

10.5

10.0

9.5

9.0

50 60 70 80 90 100

% Load on Prime Mover

Figure 11.8 Fuel consumption of prime movers using natural gas as fuel.

"

#

w f (lb=hr) 0:56(190:3) ¼ 106:6lb=hr: 11:8(900) 1:4 161:8 0:0952

HP t ¼ (3) 1 ¼ 137:7hp

The volumetric fuel requirement is 229:2 0:4 11:8

106:6 137:7 137:7

q f (gallons=hr) ¼ 15:4 gallons=hr: HP r ¼ ¼ ¼ 168:1hp

6:9 e m e v 0:90(0:9103)

2. Operating at 6,000 ft, HP in ¼ 300(1 0:22) ¼ 234 hp > 168:1 hp, so okay:

the atmospheric pressure at an elevation of 6,000 is about 161:8

11.8 psia (Lyons et al., 2001). Figure 11.9 shows a power PR ¼ ¼ 0:718 or 71:8%

reduction of 22%. 234

r ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi Figure 11.7 shows that a fuel usage of 0.54 lb/hp-hr at

3 150 þ 11:8 71.8% power ratio. Thus,

r s ¼ ¼ 2:39

11:8

w f (lbs=hr) 0:54(168:1) ¼ 90:8 lbs=hr

e v ¼ 0:96 1 0:06 (2:39) 0:714 1 ¼ 0:9013 90:8 :

q f (gallons=hr) ¼ 13:2 gallons=hr

6:9