Page 196 -

P. 196

HIGH-RATE GRANULAR MEDIA FILTRATION 8.15

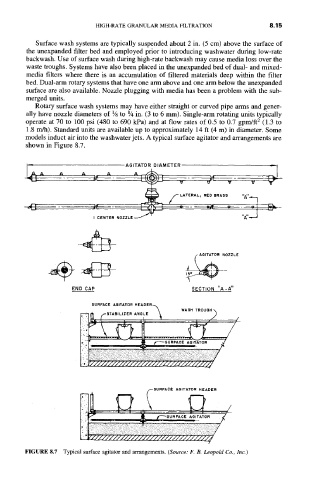

Surface wash systems are typically suspended about 2 in. (5 cm) above the surface of

the unexpanded filter bed and employed prior to introducing washwater during low-rate

backwash. Use of surface wash during high-rate backwash may cause media loss over the

waste troughs. Systems have also been placed in the unexpanded bed of dual- and mixed-

media filters where there is an accumulation of filtered materials deep within the filter

bed. Dual-arm rotary systems that have one arm above and one arm below the unexpanded

surface are also available. Nozzle plugging with media has been a problem with the sub-

merged units.

Rotary surface wash systems may have either straight or curved pipe arms and gener-

ally have nozzle diameters of 1~ to 1A in. (3 to 6 mm). Single-arm rotating units typically

operate at 70 to 100 psi (480 to 690 kPa) and at flow rates of 0.5 to 0.7 gpm/ft 2 (1.3 to

1.8 m/h). Standard units are available up to approximately 14 ft (4 m) in diameter. Some

models induct air into the washwater jets. A typical surface agitator and arrangements are

shown in Figure 8.7.

AGITATORA_j~_.~DIAMETER r'~

A A

f LATERAL I RED BRASS '~'

J~

vpL O - -

I CENTER NOZZLE "~'~ LTJ~

ZZLE

~

END CAP SECTION "A - A"

.~. . / /

'

BURFACE AGITATOR HEADER

~

7

FIGURE 8.7 Typical surface agitator and arrangements. (Source: F. B. Leopold Co., Inc.)