Page 194 -

P. 194

HIGH-RATE GRANULAR MEDIA FILTRATION 8.13

t FfLTER BOX 1

_ Z

WATER LEVEL

, FILTERING HEAD

[ z ,L ~, .,./

PLENUM/ [ DIRECTION OF FLOW DURING BACKWASHING L DIRECTION OF FLOW DURING FILTERING

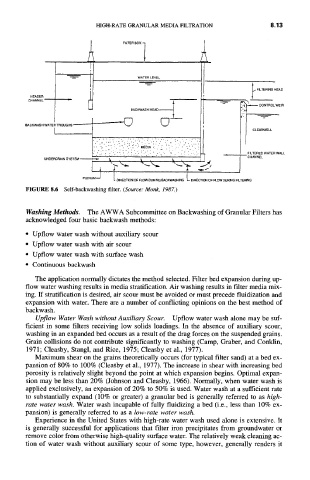

FIGURE 8.6 Self-backwashing filter. (Source: Monk, 1987.)

Washing Methods. The AWWA Subcommittee on Backwashing of Granular Filters has

acknowledged four basic backwash methods:

• Upflow water wash without auxiliary scour

• Upflow water wash with air scour

• Upflow water wash with surface wash

• Continuous backwash

The application normally dictates the method selected. Filter bed expansion during up-

flow water washing results in media stratification. Air washing results in filter media mix-

ing. If stratification is desired, air scour must be avoided or must precede fluidization and

expansion with water. There are a number of conflicting opinions on the best method of

backwash.

Upflow Water Wash without Auxiliary Scour. Upflow water wash alone may be suf-

ficient in some filters receiving low solids loadings. In the absence of auxiliary scour,

washing in an expanded bed occurs as a result of the drag forces on the suspended grains.

Grain collisions do not contribute significantly to washing (Camp, Graber, and Conklin,

1971; Cleasby, Stangl, and Rice, 1975; Cleasby et al., 1977).

Maximum shear on the grains theoretically occurs (for typical filter sand) at a bed ex-

pansion of 80% to 100% (Cleasby et al., 1977). The increase in shear with increasing bed

porosity is relatively slight beyond the point at which expansion begins. Optimal expan-

sion may be less than 20% (Johnson and Cleasby, 1966). Normally, when water wash is

applied exclusively, an expansion of 20% to 50% is used. Water wash at a sufficient rate

to substantially expand (10% or greater) a granular bed is generally referred to as high-

rate water wash. Water wash incapable of fully fluidizing a bed (i.e., less than 10% ex-

pansion) is generally referred to as a low-rate water wash.

Experience in the United States with high-rate water wash used alone is extensive. It

is generally successful for applications that filter iron precipitates from groundwater or

remove color from otherwise high-quality surface water. The relatively weak cleaning ac-

tion of water wash without auxiliary scour of some type, however, generally renders it