Page 292 -

P. 292

10,36 CHAPTER TEN

Aqueous Two-Chemical System. The earliest systems produced chlorine dioxide by sim-

ply pumping a sodium chlorite solution into a chlorine solution, followed by a short re-

action time. Acceptable yields were achieved by feeding 200% to 300% more chlorine

than the stoichiometric requirements. The chlorine dioxide solution from a generator of

this type contains high levels of chlorine in addition to chlorine dioxide.

With the discovery that potentially toxic chlorinated organics are generated by the re-

action of chlorine and naturally occurring humic substances in water supplies, plus the

growing interest in chlorine dioxide as a replacement for some chlorination practices, gen-

eration methods were sought that would produce a chlorine-free chlorine dioxide. One of

the most common methods for chlorine dioxide generation currently in use that strives to

meet this requirement is the pH-adjusted method.

The pH-adjusted system uses hydrochloric acid fed into the chlorine solution before

reaction with the sodium chlorite. The acid feed serves to shift the chlorine solution equi-

librium and the chlorine hydrolysis equilibrium, favoring hypochlorous acid and molec-

ular chlorine. The acid feed must be carefully controlled so that the pH of the chlorine

dioxide solution can be maintained between 2 and 3. Yield is reduced at both higher and

lower pH values. Yields of more than 90% have been reported from the pH-adjusted sys-

tem, with approximately 7% excess (unreacted) chlorine remaining in the solution.

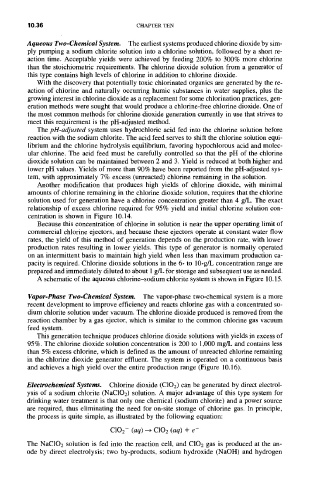

Another modification that produces high yields of chlorine dioxide, with minimal

amounts of chlorine remaining in the chlorine dioxide solution, requires that the chlorine

solution used for generation have a chlorine concentration greater than 4 g/L. The exact

relationship of excess chlorine required for 95% yield and initial chlorine solution con-

centration is shown in Figure 10.14.

Because this concentration of chlorine in solution is near the upper operating limit of

commercial chlorine ejectors, and because these ejectors operate at constant water flow

rates, the yield of this method of generation depends on the production rate, with lower

production rates resulting in lower yields. This type of generator is normally operated

on an intermittent basis to maintain high yield when less than maximum production ca-

pacity is required. Chlorine dioxide solutions in the 6- to 10-g/L concentration range are

prepared and immediately diluted to about 1 g/L for storage and subsequent use as needed.

A schematic of the aqueous chlorine-sodium chlorite system is shown in Figure 10.15.

Vapor-Phase Two-Chemical System. The vapor-phase two-chemical system is a more

recent development to improve efficiency and reacts chlorine gas with a concentrated so-

dium chlorite solution under vacuum. The chlorine dioxide produced is removed from the

reaction chamber by a gas ejector, which is similar to the common chlorine gas vacuum

feed system.

This generation technique produces chlorine dioxide solutions with yields in excess of

95%. The chlorine dioxide solution concentration is 200 to 1,000 mg/L and contains less

than 5% excess chlorine, which is defined as the amount of unreacted chlorine remaining

in the chlorine dioxide generator effluent. The system is operated on a continuous basis

and achieves a high yield over the entire production range (Figure 10.16).

Electrochemical Systems. Chlorine dioxide (CIO2) can be generated by direct electrol-

ysis of a sodium chlorite (NaC102) solution. A major advantage of this type system for

drinking water treatment is that only one chemical (sodium chlorite) and a power source

are required, thus eliminating the need for on-site storage of chlorine gas. In principle,

the process is quite simple, as illustrated by the following equation:

C102- (aq) ~ C102 (aq) + e-

The NaCIO2 solution is fed into the reaction cell, and C102 gas is produced at the an-

ode by direct electrolysis; two by-products, sodium hydroxide (NaOH) and hydrogen