Page 299 -

P. 299

OXIDATION AND DISINFECTION 18.43

to 2,000 Hz). The medium-frequency design has become the most common, with each

manufacturer optimizing operating conditions to balance the interacting factors. Recent

design improvements involving dielectric materials, gap width, and better methods of re-

moving heat from the ozone cell have drastically improved the performance and capabil-

ities of ozone generation.

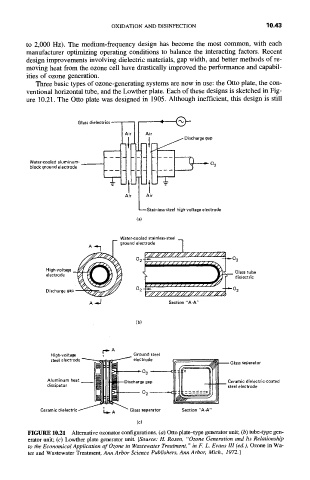

Three basic types of ozone-generating systems are now in use: the Otto plate, the con-

ventional horizontal tube, and the Lowther plate. Each of these designs is sketched in Fig-

ure 10.21. The Otto plate was designed in 1905. Although inefficient, this design is still

.- Q-

Glass dielect

Air

| ~ Discharge gap

Water-cooled aluminum-

~ ~ 0 3

block ground electrode

Air Air

--Stainless steel high-voltage electrode

(a)

_ Water-cooled stainless-steel

ground electrode -7

A~q

H igh-voltagep~

~ Glass tube

electrode

/~r dielectric

02_~ ,it . . . . . . . . . . . . _~03

Discharge ga

[////////////////////V///A

A~

Section "A-A"

(b)

I-=~A

High-voltage i ~ Ground steel

steel electrode ~ electrode

Glass separator

Ceramic dielectric-coated

d,ss,pa,or I IIIINF ..... g°P steel electrode

Section "A-A"

(c)

FIGURE 10.21 Alternative ozonator configurations. (a) Otto plate-type generator unit; (b) tube-type gen-

erator unit; (c) Lowther plate generator unit. [Source: H. Rosen, "'Ozone Generation and Its Relationship

to the Economical Application of Ozone in Wastewater Treatment," in F. L. Evans lli (ed.), Ozone in Wa-

ter and Wastewater Treatment, Ann Arbor Science Publishers, Ann Arbor, Mich., 1972.]