Page 314 -

P. 314

OXIDATION AND DISINFECTION 10,55

improved transfer efficiency. However, the corresponding decrease in gas flow rates may

significantly change the hydrodynamics within the contact basin, making uniform con-

tacting (distribution of the ozone throughout the liquid) much less certain.

Certain characteristics of the water itself can also influence the ozone transfer rate, in-

cluding temperature, pH, and water quality. The solubility of ozone increases with in-

creasing temperatures, and thus the transfer rate will increase at higher temperatures. As

pH increases, the transfer rate will increase. The presence of ozone-reactive materials, in-

cluding organics, iron, or manganese, will increase mass-transfer efficiency.

Common Types of Contactors. Types of contactors that are commonly used include

• Conventional fine bubble

• Turbine

• Packed column

• Injectors

• Deep U-tube

The selection of contactor type depends on many factors, including site considerations

and economics, but most often the contactor should be selected based on the specific treat-

ment objective. Appropriate choices are indicated in Table 10.9.

Fine Bubble Contactors. The fine bubble diffuser contactor consists of a series of

over/underbaffled cells. Ozone is applied to some or all cells through a grid of ceramic

diffusers at the bottom of the basin. The fine bubble diffuser contact basin is the most

widely used contactor. Its prevalence is justified by many factors, including

• No moving parts

• Adaptable to both rapid and slow reactions

• Adaptable to high transfer efficiency

• Adaptable to high hydraulic efficiency (T10/HRT, where HRT is the theoretical hy-

draulic retention time)

In an effort to improve transfer efficiency, the depth of bubble contactors has increased

over the years to the current practice of 20 to 22 ft (6 to 7 m) over the diffusers. Further

increases in depth yield only marginal improvement in transfer efficiency, especially at

low ozone doses.

Distribution of gas throughout the liquid must be carefully considered, especially in

the design of disinfection applications where successful operation cannot be directly mea-

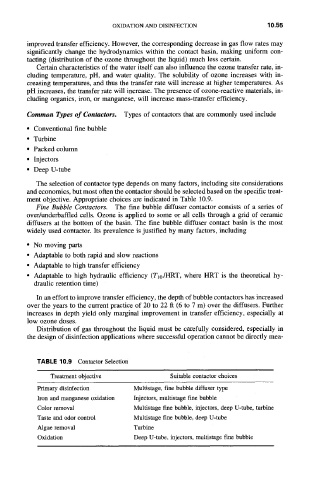

TABLE 10.9 Contactor Selection

Treatment objective Suitable contactor choices

Primary disinfection Multistage, fine bubble diffuser type

Iron and manganese oxidation Injectors, multistage fine bubble

Color removal Multistage fine bubble, injectors, deep U-tube, turbine

Taste and odor control Multistage fine bubble, deep U-tube

Algae removal Turbine

Oxidation Deep U-tube, injectors, multistage fine bubble