Page 316 -

P. 316

OXIDATION AND DISINFECTION 10.57

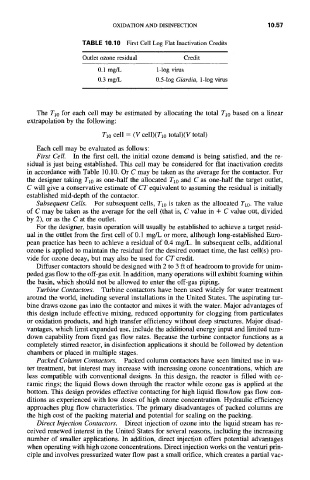

TABLE 10.10 First Cell Log Flat Inactivation Credits

Outlet ozone residual Credit

O. 1 mg/L l-log virus

0.3 mg/L 0.5-log Giardia, l-log virus

The Tl0 for each cell may be estimated by allocating the total T10 based on a linear

extrapolation by the following:

T10 cell = (V cell)(T10 total)(V total)

Each cell may be evaluated as follows:

First Cell. In the first cell, the initial ozone demand is being satisfied, and the re-

sidual is just being established. This cell may be considered for flat inactivation credits

in accordance with Table 10.10. Or C may be taken as the average for the contactor. For

the designer taking T10 as one-half the allocated T10 and C as one-half the target outlet,

C will give a conservative estimate of CT equivalent to assuming the residual is initially

established mid-depth of the contactor.

Subsequent Cells. For subsequent cells, T10 is taken as the allocated T10. The value

of C may be taken as the average for the cell (that is, C value in + C value out, divided

by 2), or as the C at the outlet.

For the designer, basin operation will usually be established to achieve a target resid-

ual in the outlet from the first cell of 0.1 mg/L or more, although long-established Euro-

pean practice has been to achieve a residual of 0.4 mg/L. In subsequent cells, additional

ozone is applied to maintain the residual for the desired contact time, the last cell(s) pro-

vide for ozone decay, but may also be used for CT credit.

Diffuser contactors should be designed with 2 to 3 ft of headroom to provide for unim-

peded gas flow to the off-gas exit. In addition, many operations will exhibit foaming within

the basin, which should not be allowed to enter the off-gas piping.

Turbine Contactors. Turbine contactors have been used widely for water treatment

around the world, including several installations in the United States. The aspirating tur-

bine draws ozone gas into the contactor and mixes it with the water. Major advantages of

this design include effective mixing, reduced opportunity for clogging from particulates

or oxidation products, and high transfer efficiency without deep structures. Major disad-

vantages, which limit expanded use, include the additional energy input and limited turn-

down capability from fixed gas flow rates. Because the turbine contactor functions as a

completely stirred reactor, in disinfection applications it should be followed by detention

chambers or placed in multiple stages.

Packed Column Contactors. Packed column contactors have seen limited use in wa-

ter treatment, but interest may increase with increasing ozone concentrations, which are

less compatible with conventional designs. In this design, the reactor is filled with ce-

ramic rings; the liquid flows down through the reactor while ozone gas is applied at the

bottom. This design provides effective contacting for high liquid flow/low gas flow con-

ditions as experienced with low doses of high ozone concentration. Hydraulic efficiency

approaches plug flow characteristics. The primary disadvantages of packed columns are

the high cost of the packing material and potential for scaling on the packing.

Direct Injection Contactors. Direct injection of ozone into the liquid stream has re-

ceived renewed interest in the United States for several reasons, including the increasing

number of smaller applications. In addition, direct injection offers potential advantages

when operating with high ozone concentrations. Direct injection works on the venturi prin-

ciple and involves pressurized water flow past a small orifice, which creates a partial vac-