Page 471 -

P. 471

ACTIVATED CARBON PROCESSES 14,19

/ /

. 4" " " , ~4 "'

•., ".4

!'..:?'..?'i;:; ..~.:~,:..!.=:...:"...: .., .. .... . . " , . : " ~ . ,' ."" ..

" ' "i " 'C

~ . 4. • , .. ..-

• .,....... ,.. ~. ...,....~:......,;..-~ ... ;' • .. • • . 4~" . •

":~ • .

"• •

.~. ,' •

~

::.:.'.{~?,~:!":":~?:.7'.:.i..:~:i:.::-::;:::"-~:/ • . ".; •....... :..-

Concrete

-- GAC Filter Box

l ~ Stainless Steel Wedge Wire

Underdrain Lateral

- - Stainless Steel

Underdrain Collector

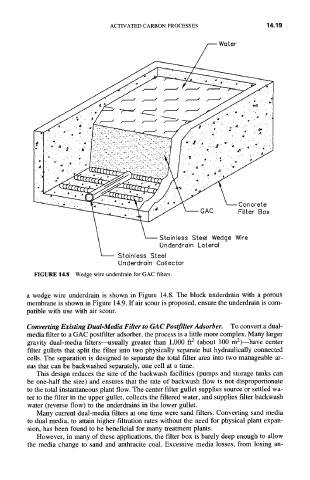

FIGURE 14.8 Wedge wire underdrain for GAC filters.

a wedge wire underdrain is shown in Figure 14.8. The block underdrain with a porous

membrane is shown in Figure 14.9. If air scour is proposed, ensure the underdrain is com-

patible with use with air scour.

Converting Existing Dual-Media Filter to GA C Postfilter Adsorber. To convert a dual-

media filter to a GAC postfilter adsorber, the process is a little more complex. Many larger

gravity dual-media filters--usually greater than 1,000 ft 2 (about 100 m2)--have center

filter gullets that split the filter into two physically separate but hydraulically connected

cells. The separation is designed to separate the total filter area into two manageable ar-

eas that can be backwashed separately, one cell at a time.

This design reduces the size of the backwash facilities (pumps and storage tanks can

be one-half the size) and ensures that the rate of backwash flow is not disproportionate

to the total instantaneous plant flow. The center filter gullet supplies source or settled wa-

ter to the filter in the upper gullet, collects the filtered water, and supplies filter backwash

water (reverse flow) to the underdrains in the lower gullet.

Many current dual-media filters at one time were sand filters. Converting sand media

to dual media, to attain higher filtration rates without the need for physical plant expan-

sion, has been found to be beneficial for many treatment plants.

However, in many of these applications, the filter box is barely deep enough to allow

the media change to sand and anthracite coal. Excessive media losses, from losing an-