Page 473 -

P. 473

ACTIVATED CARBON PROCESSES 14.21

BQ¢

to

te

~ash

~Filter Waste Washwater

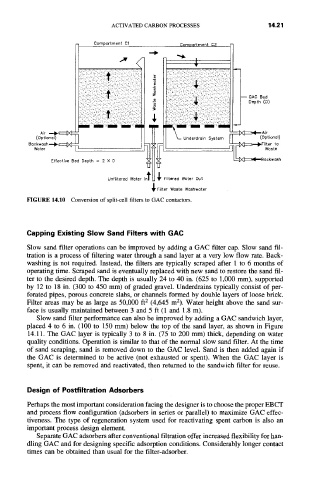

FIGURE 14.10 Conversion of split-cell filters to GAC contactors.

Capping Existing Slow Sand Filters with GAC

Slow sand filter operations can be improved by adding a GAC filter cap. Slow sand ill-

tration is a process of filtering water through a sand layer at a very low flow rate. Back-

washing is not required. Instead, the filters are typically scraped after 1 to 6 months of

operating time. Scraped sand is eventually replaced with new sand to restore the sand fil-

ter to the desired depth. The depth is usually 24 to 40 in. (625 to 1,000 mm), supported

by 12 to 18 in. (300 to 450 mm) of graded gravel. Underdrains typically consist of per-

forated pipes, porous concrete slabs, or channels formed by double layers of loose brick.

Filter areas may be as large as 50,000 ft 2 (4,645 m2). Water height above the sand sur-

face is usually maintained between 3 and 5 ft (1 and 1.8 m).

Slow sand filter performance can also be improved by adding a GAC sandwich layer,

placed 4 to 6 in. (100 to 150 mm) below the top of the sand layer, as shown in Figure

14.11. The GAC layer is typically 3 to 8 in. (75 to 200 mm) thick, depending on water

quality conditions. Operation is similar to that of the normal slow sand filter. At the time

of sand scraping, sand is removed down to the GAC level. Sand is then added again if

the GAC is determined to be active (not exhausted or spent). When the GAC layer is

spent, it can be removed and reactivated, then returned to the sandwich filter for reuse.

Design of Postfiltration Adsorbers

Perhaps the most important consideration facing the designer is to choose the proper EBCT

and process flow configuration (adsorbers in series or parallel) to maximize GAC effec-

tiveness. The type of regeneration system used for reactivating spent carbon is also an

important process design element.

Separate GAC adsorbers after conventional filtration offer increased flexibility for han-

dling GAC and for designing specific adsorption conditions. Considerably longer contact

times can be obtained than usual for the filter-adsorber.