Page 472 -

P. 472

14.20 CHAPTER FOURTEEN

~-~/4."

10-1/4"±

_

_ I_ S lO-1/4"±

i/z thick porous

I /~ /~1/2"

[ Flow During I I- Flow During

polyeth siena plate,

Filtering AV gO37e

GAC MEDIA t Baokwoshing

500 - 750 micron

~~I 3/8" self topping scre•

Heoder (typ)

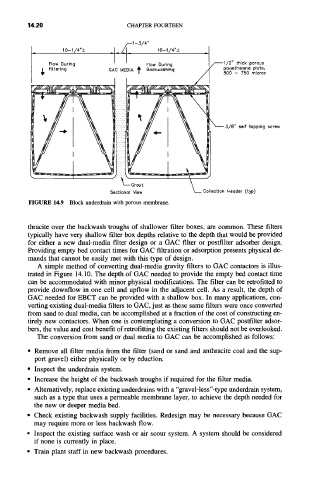

FIGURE 14.9 Block underdrain with porous membrane.

thracite over the backwash troughs of shallower filter boxes, are common. These filters

typically have very shallow filter box depths relative to the depth that would be provided

for either a new dual-media filter design or a GAC filter or postfilter adsorber design.

Providing empty bed contact times for GAC filtration or adsorption presents physical de-

mands that cannot be easily met with this type of design.

A simple method of converting dual-media gravity filters to GAC contactors is illus-

trated in Figure 14.10. The depth of GAC needed to provide the empty bed contact time

can be accommodated with minor physical modifications. The filter can be retrofitted to

provide downflow in one cell and upflow in the adjacent cell. As a result, the depth of

GAC needed for EBCT can be provided with a shallow box. In many applications, con-

verting existing dual-media filters to GAC, just as these same filters were once converted

from sand to dual media, can be accomplished at a fraction of the cost of constructing en-

tirely new contactors. When one is contemplating a conversion to GAC postfilter adsor-

bers, the value and cost benefit of retrofitting the existing filters should not be overlooked.

The conversion from sand or dual media to GAC can be accomplished as follows:

• Remove all filter media from the filter (sand or sand and anthracite coal and the sup-

port gravel) either physically or by eduction.

• Inspect the underdrain system.

• Increase the height of the backwash troughs if required for the filter media.

• Alternatively, replace existing underdrains with a "gravel-less"-type underdrain system,

such as a type that uses a permeable membrane layer, to achieve the depth needed for

the new or deeper media bed.

• Check existing backwash supply facilities. Redesign may be necessary because GAC

may require more or less backwash flow.

• Inspect the existing surface wash or air scour system. A system should be considered

if none is currently in place.

• Train plant staff in new backwash procedures.