Page 81 - 15 Dangerously Mad Projects for the Evil Genius

P. 81

60 15 Dangerously Mad Projects for the Evil Genius

1 15/16 inch (49mm)

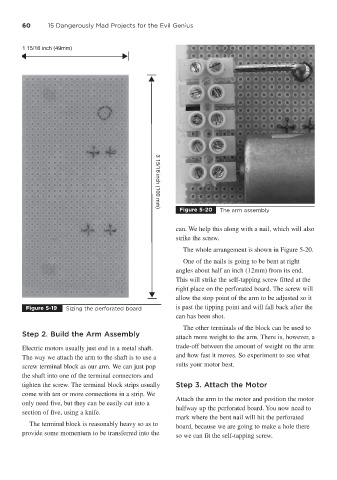

Figure 5-20 The arm assembly

3 15/16 inch (100 mm)

can. We help this along with a nail, which will also

strike the screw.

The whole arrangement is shown in Figure 5-20.

One of the nails is going to be bent at right

angles about half an inch (12mm) from its end.

This will strike the self-tapping screw fitted at the

right place on the perforated board. The screw will

allow the stop point of the arm to be adjusted so it

Figure 5-19 Sizing the perforated board is past the tipping point and will fall back after the

can has been shot.

The other terminals of the block can be used to

Step 2. Build the Arm Assembly attach more weight to the arm. There is, however, a

Electric motors usually just end in a metal shaft. trade-off between the amount of weight on the arm

The way we attach the arm to the shaft is to use a and how fast it moves. So experiment to see what

screw terminal block as our arm. We can just pop suits your motor best.

the shaft into one of the terminal connectors and

tighten the screw. The terminal block strips usually Step 3. Attach the Motor

come with ten or more connections in a strip. We

Attach the arm to the motor and position the motor

only need five, but they can be easily cut into a

halfway up the perforated board. You now need to

section of five, using a knife.

mark where the bent nail will hit the perforated

The terminal block is reasonably heavy so as to board, because we are going to make a hole there

provide some momentum to be transferred into the so we can fit the self-tapping screw.