Page 166 - 3D Fibre Reinforced Polymer Composites

P. 166

Knitted Composite Materials 155

al., 1998; Leong et al., 1999; and Khondker et al., 2001a) have reported that for 1x1 rib

and milano weft knitted composite materials, the compressive strength is significantly

better than the tensile strength whilst the compressive modulus is similar to, or slightly

less than, the tensile modulus. Examples of this behaviour are given in Table 7.4. Again

distinctly different from the tension properties;the effect of changing loop lengths and

stitch densities upon the compressive properties is far less significant. Khondker et al

2001b reported that in E-glasshnyl ester weft knitted composites (plain, rib and milano

architectures) at best only marginal improvement was observed in the compression

strength with an increase in loop length whilst negligible effect was observed on the

compressive modulus.

\ I I I

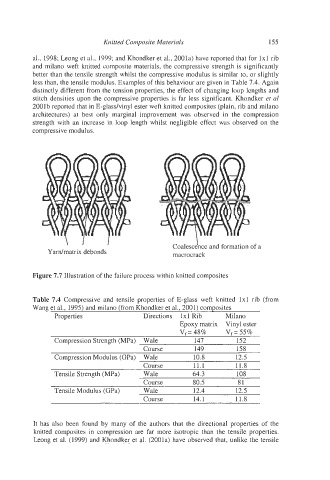

Yardmatrix debonds Coalescence and formation of a

macrocrac k

Figure 7.7 Illustration of the failure process within knitted composites

Table 7.4 Compressive and tensile properties of E-glass weft knitted 1x1 rib (from

Wang et al., 1995) and milano (from Khondker et al., 2001) composites

Properties Directions 1x1 Rib Milano

Epoxy matrix Vinyl ester

Vf = 48% Vf = 55%

Compression Strength (MPa) Wale 147 152

Course 149 158

Compression Modulus (GPa) Wale 10.8 12.5

Course 11.1 11.8

Tensile Strength (ma) Wale 64.3 108

Course 80.5 81

Tensile Modulus (GPa) Wale 12.4 12.5

Course 14.1 11.8

It has also been found by many of the authors that the directional properties of the

knitted composites in compression are far more isotropic than the tensile properties.

Leong et al. (1999) and Khondker et al. (2001a) have observed that, unlike the tensile