Page 448 - A Comprehensive Guide to Solar Energy Systems

P. 448

460 A COmPREhEnSIVE GuIdE TO SOlAR EnERGy SySTEmS

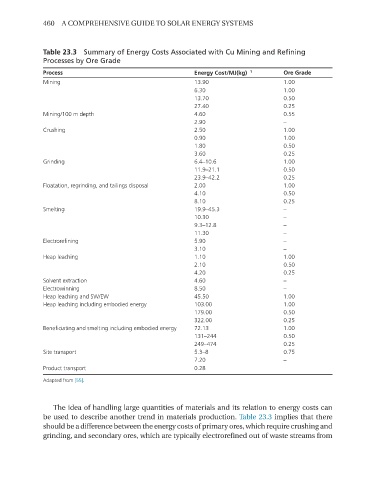

Table 23.3 Summary of Energy Costs Associated with Cu Mining and Refining

Processes by Ore Grade

Process Energy Cost/MJ(kg) −1 Ore Grade

Mining 13.90 1.00

6.30 1.00

13.70 0.50

27.40 0.25

Mining/100 m depth 4.60 0.55

2.90 –

Crushing 2.50 1.00

0.90 1.00

1.80 0.50

3.60 0.25

Grinding 6.4–10.6 1.00

11.9–21.1 0.50

23.9–42.2 0.25

Floatation, regrinding, and tailings disposal 2.00 1.00

4.10 0.50

8.10 0.25

Smelting 19.9–45.3 –

10.30 –

9.3–12.8 –

11.30 –

Electrorefining 5.90 –

3.10 –

Heap leaching 1.10 1.00

2.10 0.50

4.20 0.25

Solvent extraction 4.60 –

Electrowinning 8.50 –

Heap leaching and SW/EW 45.50 1.00

Heap leaching including embodied energy 103.00 1.00

179.00 0.50

322.00 0.25

Beneficiating and smelting including embodied energy 72.13 1.00

131–244 0.50

249–474 0.25

Site transport 5.3–8 0.75

7.20 –

Product transport 0.28

Adapted from [55].

The idea of handling large quantities of materials and its relation to energy costs can

be used to describe another trend in materials production. Table 23.3 implies that there

should be a difference between the energy costs of primary ores, which require crushing and

grinding, and secondary ores, which are typically electrorefined out of waste streams from