Page 221 - A Practical Companion to Reservoir Stimulation

P. 221

PRACTICAL COMPANION TO RESERVOIR STIMULATION

hoses should be enclosed in a hose cover to prevent the oil frac tanks must be spotted so that the remaining equipment

from spraying on hot engine components of the trucks, should can also fit on location. Special attention should be given to

the hose ever leak. the type of equipment on location during the treatment.

Care must be taken to ensure that there is no smoking on Often, other contractors (workover rigs, logging trucks, etc.)

location. It is a good idea to have all personnel check matches will be on location, and allowances for the positioning of this

and lighters when they arrive on location to prevent them additional equipment must also be made. Water haulers must

from unintentionally lighting a match. Finally, it is a good have access to the tanks so they can be quickly and easily

idea to have fire-fighting equipment on location and ready to filled.

operate. In this way, a small fire may be contained before it Care should be taken to always spot tanks on high ground.

has a chance to spread and become a major disaster. Blending equipment is required to suck the fluid from these

tanks aihigh rates. By placing the tanks on high ground, the

P-7.1.8: Safety Equipment net positive suction head (npsh) is increased, and the odds of

Each person on location should wear proper safety equip- losing prime on the blender are reduced. Tanks should never

ment to minimize the risk of personal injury. Hard hats, hard- be spotted below the level of other equipment where the

toed shoes and safety glasses should be the minimum level of centrifugal pumps of the blender would have to lift fluid

safety equipment worn on location. Other equipment such as against gravity. Such placement compromises the perfor-

hearing protection, goggles, fire-retardant fabrics and filter mance of the blender, especially as fluid is drawn down and

masks should be worn if exposure to their respective condi- the tank nears empty.

tions is a possibility. Wearing the proper safety equipment is Also, to improve fluid flow and the suction properties of

a simple step that can be taken to create a positive safety the blender, a common manifold should be used to connect all

atmosphere on location. the frac tanks together. In some geographical areas the frac

Additional specific safety considerations are discussed in tanks will be equipped with this type of manifold as a perma-

the following sections. nent connection. These tanks are connected with a section of

flexible 8-in. hose. In other areas it may be necessary to lay a

P-7.2: Backside Organization portable manifold in front of the tanks so that all the frac tanks

Fracturing treatments are generally organized in an orderly can be tied together.

fashion from fluid storage (frac tanks) to the wellhead. The The quality and condition of frac tanks directly impact the

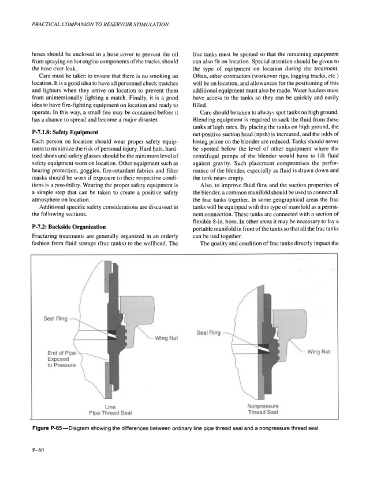

Figure P-65-Diagram showing the differences between ordinary line pipe thread seal and a nonpressure thread seal.

P- 60