Page 222 - A Practical Companion to Reservoir Stimulation

P. 222

PRACTICAL CONSIDERATIONS FOR FRACTURE TREATMENT DESIGN

ultimate success of the treatment. All tanks must be emptied is either leaking or missing. If the bull plug is removed after

and cleaned after each treatment and before they are refilled the tank is filled, significant amounts of fluid may spill before

for subsequent jobs. If not removed during cleaning operations, another connection can be made to control the flow. A frac

contaminants from previous use can undermine the fluid tank spill is potentially disastrous when oil-base fluids are

quality. pumped. Many of the worst location fires involving stimula-

Lined tanks help to ensure the fluid quality after fluid has tion treatments have been linked to frac tank leaks and faulty

been added to the tank. The lining prevents oxidation valves. Even when the fluids are water base, bull plugs

byproducts from contaminating the fluids. Excessive metal should not be removed from the frac tank. Large amounts of

ions can aggravate break and crosslink problems of standard water, expensive premixed chemicals and time may be lost.

fracturing fluids. The lining itself should be periodically In different regionalized areas the style of the "standard"

examined to ensure that holes are not present. Once holes frac tank will vary significantly. Some of the most common

have developed, fluid can get between the lining and the tank tank styles in use today are rectangular flat bottom, rectangu-

wall. Water that has penetrated the lining may become a lar V-bottom, horizontal cylindrical and upright cylindrical.

source of bacteria or oxidation since it is never completely The shape of the rectangular V-bottom and the horizontal

drained from the tank. cylindrical tanks helps minimize the amount of fluid left in

All valves must be checked to ensure they are in working the tank bottoms. These styles can generally be very nearly

order. Frac tanks with bull plugs covering a valve should emptied, leaving only a few barrels of fluid, before blender

never be used since it is impossible to determine if the valve suction is lost. The amount of fluid left in the tanks is

Pumpers

Preferred Wind

F

Directions

Frac Pump

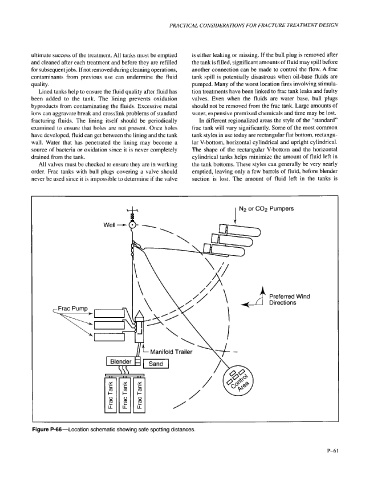

Figure P-66-Location schematic showing safe spotting distances.

P-6 1