Page 128 - Adsorbents fundamentals and applications

P. 128

CARBON MOLECULAR SIEVES 113

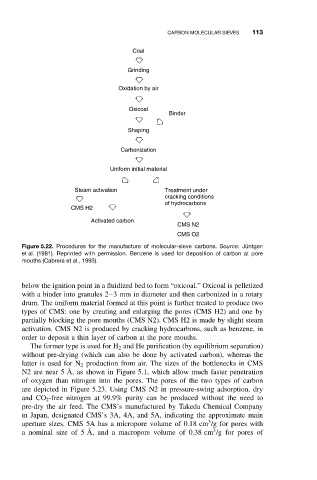

Coal

Grinding

Oxidation by air

Oxicoal

Binder

Shaping

Carbonization

Uniform initial material

Steam activation Treatment under

cracking conditions

of hydrocarbons

CMS H2

Activated carbon

CMS N2

CMS O2

Figure 5.22. Procedures for the manufacture of molecular-sieve carbons. Source:J ¨ untgen

et al. (1981). Reprinted with permission. Benzene is used for deposition of carbon at pore

mouths (Cabrera et al., 1993).

below the ignition point in a fluidized bed to form “oxicoal.” Oxicoal is pelletized

with a binder into granules 2–3 mm in diameter and then carbonized in a rotary

drum. The uniform material formed at this point is further treated to produce two

types of CMS: one by creating and enlarging the pores (CMS H2) and one by

partially blocking the pore mouths (CMS N2). CMS H2 is made by slight steam

activation. CMS N2 is produced by cracking hydrocarbons, such as benzene, in

order to deposit a thin layer of carbon at the pore mouths.

The former type is used for H 2 and He purification (by equilibrium separation)

without pre-drying (which can also be done by activated carbon), whereas the

latter is used for N 2 production from air. The sizes of the bottlenecks in CMS

N2 are near 5 ˚ A, as shown in Figure 5.1, which allow much faster penetration

of oxygen than nitrogen into the pores. The pores of the two types of carbon

are depicted in Figure 5.23. Using CMS N2 in pressure-swing adsorption, dry

and CO 2 -free nitrogen at 99.9% purity can be produced without the need to

pre-dry the air feed. The CMS’s manufactured by Takeda Chemical Company

in Japan, designated CMS’s 3A, 4A, and 5A, indicating the approximate main

3

aperture sizes. CMS 5A has a micropore volume of 0.18 cm /g for pores with

3

a nominal size of 5 ˚ A, and a macropore volume of 0.38 cm /g for pores of