Page 241 - Adsorbents fundamentals and applications

P. 241

226 π-COMPLEXATION SORBENTS AND APPLICATIONS

2

Amount adsorbed (m mol/g) 1.5

1

0.5

1,5-Hexadiene

1-Hexene

0

1.0E-05 1.0E-04 1.0E-03 1.0E-02 1.0E-01 1.0E+00

Partial pressure (atm)

◦

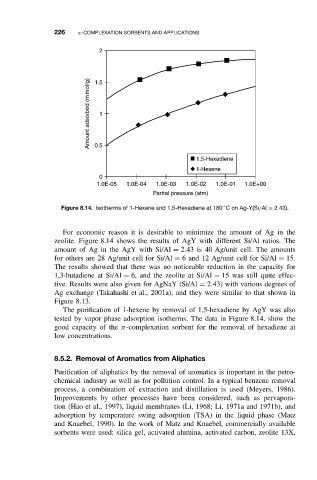

Figure 8.14. Isotherms of 1-Hexene and 1,5-Hexadiene at 180 C on Ag-Y(Si/Al = 2.43).

For economic reason it is desirable to minimize the amount of Ag in the

zeolite. Figure 8.14 shows the results of AgY with different Si/Al ratios. The

amount of Ag in the AgY with Si/Al = 2.43 is 40 Ag/unit cell. The amounts

for others are 28 Ag/unit cell for Si/Al = 6 and 12 Ag/unit cell for Si/Al = 15.

The results showed that there was no noticeable reduction in the capacity for

1,3-butadiene at Si/Al = 6, and the zeolite at Si/Al = 15 was still quite effec-

tive. Results were also given for AgNaY (Si/Al = 2.43) with various degrees of

Ag exchange (Takahashi et al., 2001a), and they were similar to that shown in

Figure 8.13.

The purification of 1-hexene by removal of 1,5-hexadiene by AgY was also

tested by vapor phase adsorption isotherms. The data in Figure 8.14. show the

good capacity of the π-complexation sorbent for the removal of hexadiene at

low concentrations.

8.5.2. Removal of Aromatics from Aliphatics

Purification of aliphatics by the removal of aromatics is important in the petro-

chemical industry as well as for pollution control. In a typical benzene removal

process, a combination of extraction and distillation is used (Meyers, 1986).

Improvements by other processes have been considered, such as pervapora-

tion (Hao et al., 1997), liquid membranes (Li, 1968; Li, 1971a and 1971b), and

adsorption by temperature swing adsorption (TSA) in the liquid phase (Matz

and Knaebel, 1990). In the work of Matz and Knaebel, commercially available

sorbents were used: silica gel, activated alumina, activated carbon, zeolite 13X,